RIVM, P.O. Box 1, 3720 BA Bilthoven, the Netherlands Tel +31 30 274 91 11 www.rivm.nl RIVM Letter Report 320104009/2010

Comparing the BAMA indoor air and ConsExpo

inhalation models

Christiaan Delmaar Contact: Christiaan Delmaar SIR christiaan.delmaar@rivm.nlThis investigation has been performed by order and for the account of Voedsel en Waren Autoriteit (VWA), within the framework of project V/320104, Consumentenblootstelling

© RIVM 2010

Parts of this publication may be reproduced, provided acknowledgement is given to the 'National Institute for Public Health and the Environment', along with the title and year of publication.

3

Abstract

For chemical substances regulated under REACh, that are intended to be used in consumer products, REACh regulation requires that safe use of chemicals in these products is demonstrated. Such Chemical Safety Assessments (CSAs) require an evaluation of the consumer exposure to the chemical substances in the product. Due of the lack of data on exposure, this evaluation is often done by modelling. Various tools to estimate human exposure from consumer products exist. Specifically, for substances contained in consumer spray products, two modelling tools are expected to be frequently used in the development of Chemical Safety Reports: the BAMA Indoor Air model and ConsExpo. The first tool is developed by the British Aerosol Manufacturers Association (BAMA), ConsExpo is developed at RIVM. For the evaluation of Chemical Safety Reports provided by industry, insight in the differences and similarities of alternative tools and methods is required.

In this report a comparison between BAMA indoor air model and ConsExpo has been made. The assumptions and structure of both models are described. In simulations the differences in models are illustrated. The BAMA model is build on simpler assumptions than the ConsExpo spray model. The simplifications in the BAMA model are especially important in cases where the model is used to estimate exposure to low-volatile substances in sprays that are released as aerosol droplets. In these applications the BAMA model will give higher estimates than the ConsExpo model. The BAMA model predictions are expected to be unrealistically high in most of these cases. The model is only suited for screening of potential exposure for these substances.

A second limitation in the BAMA model is the assumption of instantaneous release of material. This assumption limits the applicability of the model to evaluation of short term (acute) exposures. The BAMA model is expected to be only suited for estimating longer term exposures.

Trefwoorden / Key words:

Rapport in het kort

Voor chemische stoffen die onder REACh gereguleerd worden en die bedoeld zijn om in

consumentenproducten gebruikt te worden, vereist REACh een z.g. ‘Chemical Safety Assessment (CSA)’. In een dergelijke CSA moet gedemonstreerd worden dat het gebruik van de stof in een consumentenproduct veilig is. Bij gebrek aan blootstellingsgegevens kan bij het maken van een CSA gebruik gemaakt worden van blootstellingmodellering. Er bestaan verschillende modellen voor de schatting van de blootstelling van consumenten aan chemische stoffen. Voor stoffen uit

consumentenproducten in spuitbussen m.n. zijn er twee modellen die waarschijnlijk veelvudig gebruikt zullen worden bij de ontwikkeling van CSAs. Dit zijn het ‘Indoor Air’ model van de ‘British Aerosol Manufacturers Association (BAMA)’ en het spuitbus model uit het ConsExpo programma dat is ontwikkeld door het RIVM. Voor een beoordeling van de kwaliteit van een CSA, zoals die door de industrie worden gemaakt, is het belangrijk goed inzicht te krijgen in de verschillen en overeenkomsten tussen verschillende methodes en modellen die in de praktijk gebruikt kunnen worden.

In dit rapport worden de BAMA en het ConsExpo programma met elkaar vergeleken, In het rapport worden de aannames en modelstructuur van beide modellen beschreven. De verschillen tussen beide modellen worden aan de hand van simulaties geïllustreerd.

Het BAMA model is op meer versimpelende aannames gebaseerd dan het ConsExpo spuitmodel. Deze vereenvoudigingen zijn met name van belang als het model gebruikt wordt voor het schatten van de blootstelling aan niet-vluchtige stoffen in spuitbussen die vrijkomen als aerosoldeeltjes. Voor dit type stoffen geeft het BAMA model hogere schattingen dan het ConsExpo spuitmodel. Het is de verwachting dat de BAMA schattingen in de meeste van deze gevallen onrealistisch hoog zijn. Het model is slechts geschikt voor een ruwe schatting van de mogelijke blootstelling aan deze stoffen. Een andere beperking van het BAMA model is de aanname dat het gespoten materiaal onmiddellijk vrijkomt. Deze aanname beperkt de toepasbaarheid van het BAMA model bij het schatten van kortdurige (acute) blootstellingen. Het is aan te nemen dat het BAMA model alleen geschikt is voor het schatten van langer durende blootstellingen.

Trefwoorden / Key words:

5

Contents

Summary 6

Introduction 7

1 The BAMA and ConsExpo indoor air models 8

1.1 The BAMA tool 8

1.2 The ConsExpo inhalation models 9

2 Comparing model simulations 12

2.1 The effect of gravitational deposition of aerosol particles 12

2.2 The effect of finite spray duration 16

2.3 Adjusting the BAMA tool to account for particle size distribution 18

3 Conclusions & discussion 20

Summary

In this report a comparison is made between two indoor air exposure modelling tools: the RIVM ConsExpo tool and the tool developed by the British Aerosol Manufacturing Association (BAMA). Both tools are suited to be used in Chemical Safety Assessments required under REACh, for regulated substances that are used in consumer products. For the evaluation of Chemical Safety Reports provided by industry, in which both these tools may be used, it is important to identify differences between, and limitations of these modelling tools.

ConsExpo is a stand-alone computer program, the BAMA indoor air model was developed as an excel document. The comparison made in this report focuses on differences in assumptions and formulation of the mathematical models in both tools. Implementation, user interface and guidance on how to apply the two models are only briefly discussed in cases where these may have a large impact on the

exposure estimates.

In addition, the BAMA indoor air model was developed to make exposure estimates for both

substances that are released as vapours and substances released as an aerosol. This report regards only applications of the model to the release of substances as an aerosol (i.e. from spray cans).

It was found that the BAMA indoor air model is a crude and simple model that is, in its assumptions, entirely equivalent to the ConsExpo ‘exposure to vapours: instantaneous release’ model. These models are very well suited to perform quick, effortless and robust screening estimates of exposure. In addition to this screening model, ConsExpo also offers a more advanced model to estimate aerosol exposures, the ConsExpo ‘exposure to spray’ model.

Differences between the ConsExpo spray model and the BAMA indoor air model were analysed in detail. It was found that the BAMA indoor air model predicts considerably higher air concentrations than the ConsExpo model, especially for larger aerosol particles (larger than about 5 µm). This over prediction is due to the neglect of gravitational deposition (i.e. the falling to the ground) of aerosol particles in the BAMA indoor air model. This limits the usability of the BAMA tool to screening assessments only. For more realistic and detailed exposure assessments, the ConsExpo spray model is preferred.

7

Introduction

The British Aerosol Manufacturers Association (BAMA) has developed a mathematical model to predict the indoor exposure of residents to ingredients in aerosol sprays. The model is intended to aid in chemical safety assessments for aerosol products as required under REACH. The BAMA model has been implemented in a computer tool that can be obtained free from charge at the BAMA website www.bama.co.uk.

ConsExpo is a consumer exposure estimation tool, developed at RIVM. The tool comprises a number of exposure models. Specifically, it includes models to estimate exposures to chemical substances in spray products. The ConsExpo tool includes simple first tier models, but also more complex higher tier models. The tool is recommended to be used in higher tier exposure assessments in REACH (ECHA, 2010).The ConsExpo tool can be freely obtained from www.consexpo.com.

In this report the BAMA indoor air model is compared to the indoor air models in the ConsExpo tool. The differences in model concepts are discussed and a number of simulations are performed to demonstrate under which conditions the modelled results differ from each other and under which conditions the models produce similar exposure estimates.

1

The BAMA and ConsExpo indoor air models

1.1

The BAMA tool

The BAMA indoor air model is designed to provide simple, conservative exposure estimates of residents to ingredients in aerosol sprays that are used indoors. The model is not intended to make a distinction between the type of ingredient i.e. it is assumed to be valid for propellant gases, solvents and non-volatile materials alike.

The basic assumptions in the model are:

1) the material that is released from the spray is assumed to be discharged at once from the container and distributed immediately over the entire indoor air space (room)

2) the removal of the material from the indoor air is by ventilation only

The BAMA model equation for the air concentration at time t after instantaneous discharge, perfect mixing in indoor air and removal by ventilation is given by:

(1) air s f q t room

R T

w

C

e

V

− ×× ×

=

In this equation1 airC

:indoor air concentration [mg/m3]

R

spray product discharge rate [mg/s]s

T

spray duration [seconds]f

w

fraction of the ingredient in the productroom

V

room volume [m3]q

room ventilation rate [ACH: air change per hour]t

time after spraying [hour]From (1) it follows for the (time weighted) average of the air concentration

C

air(

T

exp)

after an exposure durationT

exp:(2) exp exp exp

1

(

)

s f(1

q T)

airR T

w

C

T

e

T

V

q

− ×× ×

=

× −

×

The BAMA indoor air model has been experimentally tested in a small test room for two ingredients (a propellant gas and a solvent) contained in different sprays (Rowley et al., 2005). In these experiments, time weighted average (TWA) air concentrations emerging after application of the sprays where measured at multiple times after emission (i.e. 0.25, 8, 16 and 24 hours). The model predicted the longer TWA air concentrations well. For short durations, deviations of the experimental data from the

1

the symbols in this equation deviate from those used in the BAMA documentation. The set of symbols used in this report are chosen to simplify comparison with the ConsExpo models.

9

model predictions up to one order of magnitude where observed. These discrepancies could be attributed to incomplete mixing of the aerosol cloud in the first stages of the exposure.

The model was not tested for aerosol droplets.

It is acknowledged that the BAMA indoor air model will over predict exposures to ingredients that are released as an aerosol particle. Therefore, in the manual, it is suggested to account for the particle size distribution by including only the aerosol particles with diameters smaller than 10 µm. These are conventionally considered to represent respirable particles (CEN, 1993), (i.e. these particles will have the potential to reach the lower parts of the respiratory tract and may lead to inhalation exposure). The BAMA indoor assumes immediate dispersion of the sprayed material throughout the room in which it is released. This assumption does not account for the fact that, especially during use of the spray, near-field concentrations in may be much higher. Neglecting these effects may especially underestimate exposure when a spray is used on a person, such as fir instance a cosmetic spray (hair spray, deodorant). Such situations may be simulated using a limited distribution volume, but the BAMA indoor air model does not provide this option as a automated method.

1.2

The ConsExpo inhalation models

ConsExpo includes two different indoor air exposure models. One (the ‘exposure to vapours’ model) describes exposure to volatile substances, the other (the ‘exposure to spray’ model) the exposure to non- or low volatile substances that are released as aerosol particles.

The inhalation to vapours model comprises a number of sub-models of increasing complexity. The simplest one of which, the ‘instantaneous release’ model is exactly equivalent to the BAMA indoor air model. Equation (1) gives the air concentration after time t, also. And, similarly, equation (2) gives the TWA air concentration2

( s/ ) s f q v h t air room

R T

w

C

e

V

− + ×× ×

=

. As this ConsExpo model and the BAMA model are completely equivalent, in the remainder of this report only the ConsExpo spray model is considered.

The exposure to spray model on the other hand considers only exposure to material that remains in the aerosol droplets. The model also assumes complete mixing after spraying. In addition to ventilation, removal of material by gravitational deposition of aerosol droplets to the ground is considered in the model.

In this case the air concentration at time t after spraying is given by: (3)

and the TWA air concentration after

T

exp is given by:(4) exp exp exp

1

(

)

(1

)

(

)

q T s f air sR T

w

C

T

e

v

T

V

q

h

− ×× ×

=

× −

× +

2These remarks refer to ConsExpo 4. The ConsExpo 5 version includes the same model also as a first tier model for sprays as well. At the time of writing, version 5 is only available as a beta version.

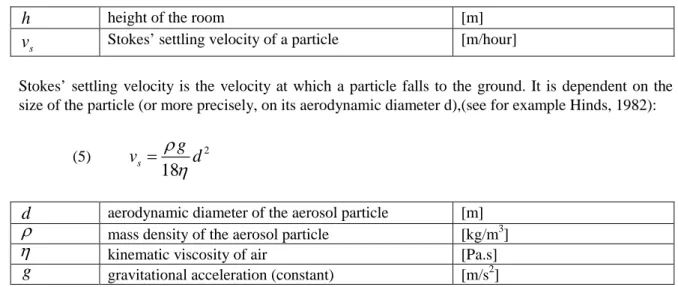

In these equations,

h

height of the room [m]s

v

Stokes’ settling velocity of a particle [m/hour]Stokes’ settling velocity is the velocity at which a particle falls to the ground. It is dependent on the size of the particle (or more precisely, on its aerodynamic diameter d),(see for example Hinds, 1982):

(5) 2

18

sg

v

ρ

d

η

=

d

aerodynamic diameter of the aerosol particle [m]ρ

mass density of the aerosol particle [kg/m3]

η

kinematic viscosity of air [Pa.s]g

gravitational acceleration (constant) [m/s2]Settling velocities for a number of particle sizes are presented in table 1 below. To arrive at the estimations in this table it is assumed that the mass density of the aerosol particle is 1 g/cm3 (i.e. equal to water). The viscosity of air at room temperature (20oC) is about 1.8x10-5 Pa.s (Hinds, 1982. p21).

Table 1. Stokes’ settling velocity for different particle diameters

d (um) vs

100 3.02E-01 m/s

20 1.21E-02 m/s

10 3.02E-03 m/s

5 7.56E-04 m/s

In addition to taking into account the removal by gravitational deposition, the ConsExpo spray model also takes into account the fact that spray duration is finite. That is, the release is not instantaneous but rather with a constant discharge rate for the duration of spraying. This additional refinement may have a significant effect on the exposure in the initial stages, but will not effect the overall, long term TWA concentrations.

Finally, the ConsExpo program also offers a default method to account for near field concentrations during spraying, which can be used to account for initial higher concentrations when a spray is used on a person. During spraying towards an exposed person a cloud around the person is assumed, after spraying complete mixing is assumed. This method is assumed to be useful in making conservative estimates of the exposure in the initial phases, but experimental validation of this concept and indications of what constitutes a reasonable value for the initial cloud volume are lacking.

The ConsExpo spray model has been validated experimentally by measurements on air concentrations in a climate chamber for a number of sprays (Delmaar, et al. 2009).

2

Comparing model simulations

In this section the effects of the differences in model concepts between the BAMA and ConsExpo spray models described above are studied quantitatively. To this end, the mathematical models have been reimplemented in the Mathematica modelling tool.

The quantitative comparison focussed on the two aspects identified above: in section 2.1 the effect of including the gravitational settling of aerosol droplets is studied. In section 2.2 the effect of explicitly including a finite (non-zero) spray duration is considered.

Finally, the suggestion in the BAMA manual to deal with aerosol particle size distributions by considering only particles with diameter smaller than 10 µm is tested in section 2.3. Here the BAMA approach is compared with ConsExpo modelling for two sprays for which the particle size distribution is known.

2.1

The effect of gravitational deposition of aerosol particles

As described in section 1.2 the ConsExpo model considers the removal of aerosols from indoor air by gravitational deposition in addition to ventilation of indoor air.

The rate at which particles are removed from indoor air by deposition is given by: (6)

where the particle size-dependent Stokes’ settling velocity

v

sis determined from (5).The removal rate of material due to ventilation on the other hand is (7)

Comparing (6) and (7) makes clear that the differences in the modelling approaches are only important if , or at least .

The ventilation rate in homes ranges from about 0.2-3 ACH (Bremmer, et al., 2006). Assuming a room height of 2.5 m, it is found from (5) that for particles with diameter of 2-8 µm the removal of material by ventilation will be comparable by that of gravitational deposition. For particles with much smaller diameters (e.g. smaller than 0.5µm), room ventilation will be the dominant process of removal and inclusion of gravitational deposition in the model will not have a significant effect on the model predictions. For particles this small, the BAMA indoor air model and the ConsExpo spray model are expected to produce comparable exposure estimates.

Not including gravitational deposition for particles of ~2µm and larger in the model will lead to over-estimating the indoor air concentrations. For these particles the BAMA indoor air model is expected to provide higher and hence more conservative exposure estimates than the ConsExpo spray model. These assumptions have been tested in model simulations. Both the BAMA indoor air and ConsExpo spray models have been implemented in Mathematica. The models have been used to simulate air concentrations in a typical, representative indoor exposure scenario.

s

v

q

h

≥

~

sv

q

h

s dep airv

R

C

h

= − ×

vent airR

= − ×

q C

13

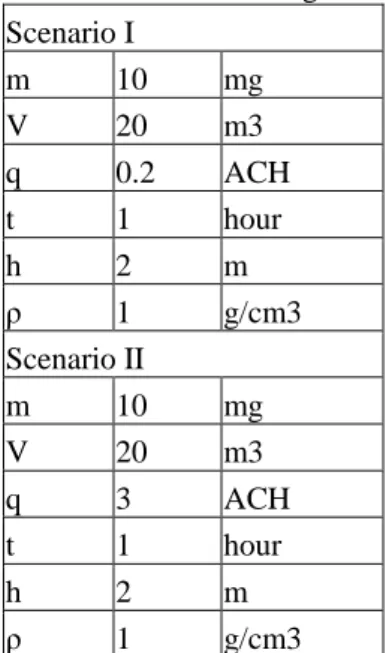

In the simulations, the following assumptions were made: 10 mg of material was released in a small room of 20 m3. The emission was assumed to be instantaneous.

The air concentrations have been simulated up to 1 hour after emission.

The simulations I and II are performed for mono-disperse particle size distributions (sizes of 0.5, 5 and 20 µm). In simulation I the room ventilation is set to 0.2 ACH a rather low value, in simulation II to 3 ACH, a high, but realistic value.

Table 2. Scenario settings for the model simulations Scenario I m 10 mg V 20 m3 q 0.2 ACH t 1 hour h 2 m ρ 1 g/cm3 Scenario II m 10 mg V 20 m3 q 3 ACH t 1 hour h 2 m ρ 1 g/cm3 Results

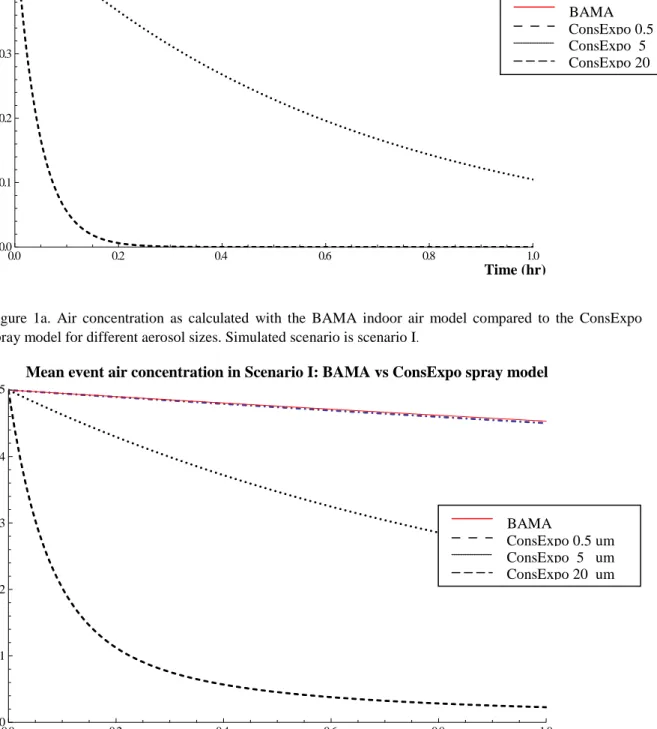

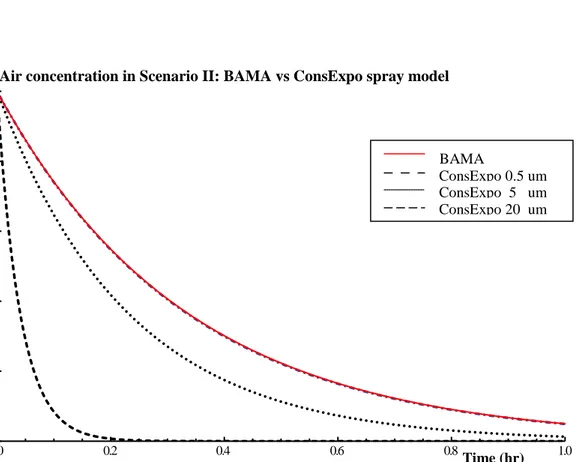

Results of the simulations have been plotted in figures 1 and 2. For both simulations it is seen that the ConsExpo spray model more closely resembles the BAMA model with decreasing particle size. As the aerosol particle size drops to 0.5 µm the BAMA and ConsExpo model predictions become almost undistinguishable, as was expected from the analysis given above.

Comparing simulation I and II it is seen that the difference between ConsExpo spray model and BAMA model for the larger aerosol particles decreases with increasing ventilation fold: the difference, for example, the simulated mean event air concentration between BAMA and the ConsExpo spray model for particle diameter 5 µm is much smaller in scenario II than in scenario I. This is again completely in agreement with the discussion above.

Air concentration in Scenario I: BAMA vs ConsExpo spray model

Figure 1a. Air concentration as calculated with the BAMA indoor air model compared to the ConsExpo

spray model for different aerosol sizes. Simulated scenario is scenario I.

0.0 0.2 0.4 0.6 0.8 1.0 0.0 0.1 0.2 0.3 0.4 0.5

Figure 1b. Mean event air concentration as calculated with the BAMA indoor air model compared to the ConsExpo spray model for different aerosol sizes. Simulated scenario is scenario I.

0.0 0.2 0.4 0.6 0.8 1.0 0.0 0.1 0.2 0.3 0.4 0.5 ConsExpo 0.5 um BAMA ConsExpo 5 um ConsExpo 20 um ConsExpo 0.5 um BAMA ConsExpo 5 um ConsExpo 20 um Concentration (mg/m3) Concentration (mg/m3) Time (hr)

Mean event air concentration in Scenario I: BAMA vs ConsExpo spray model

15

Air concentration in Scenario II: BAMA vs ConsExpo spray model

0.0 0.2 0.4 0.6 0.8 1.0 0.0 0.1 0.2 0.3 0.4 0.5

Figure 2a. Air concentration as calculated with the BAMA indoor air model compared to the ConsExpo

spray model for different aerosol sizes. Simulated scenario is scenario II.

0.0 0.2 0.4 0.6 0.8 1.0 0.0 0.1 0.2 0.3 0.4 0.5

Figure 2b. Mean even air concentration as calculated with the BAMA indoor air model compared to the ConsExpo spray model for different aerosol sizes. Simulated scenario is scenario II.

ConsExpo 0.5 um BAMA ConsExpo 5 um ConsExpo 20 um ConsExpo 0.5 um BAMA ConsExpo 5 um ConsExpo 20 um

Mean event air concentration in Scenario II: BAMA vs ConsExpo spray model

Concentration (mg/m3) Time (hr) Concentration (mg/m3) Time (hr)

2.2

The effect of finite spray duration

When it is not assumed that the sprayed material is immediately released, as in the BAMA indoor air model, but rather is released in some finite spray duration Tspray, as is assumed in the ConsExpo spray

model, the simulated air concentration profiles change somewhat.

ConsExpo models the air concentration of aerosol particles with diameter d, including a finite spray duration as: (8)

1

(1

( / ))

/

s f q v h t air room sR w

C

e

V

q

v

h

− + ××

=

−

+

during spraying (i.e. t < Tspray)

And, (9)

1

(1

( / ))

( / ) ( )/

s spray s spray q v h T q v h t T f air room sR w

C

e

e

V

q

v

h

− + × − + × −×

=

−

×

+

(see Delmaar et al. (2005) for a more elaborate description of the ConsExpo model).

For typical consumer applications, spray durations will be short (i.e. ranging from several seconds to a few minutes). Differences in BAMA and ConsExpo spray model evaluations due to the assumption of immediate release in the BAMA indoor air model will be expected for the initial phase (that of the use of the spray) of exposure only. The long term (compared to the spray duration) average concentrations will not be notably affected.

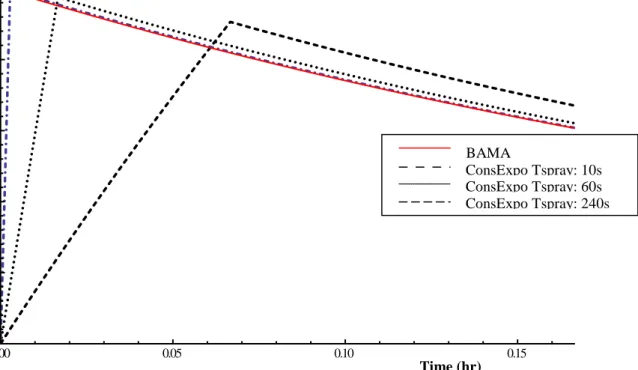

In figure 3 the differences between a ConsExpo simulation for particles with a diameter of 0.5 µm and the BAMA indoor air model are shown. To reduce the influence of differences in modeling due to gravitational deposition, the settings of the scenario are chosen as in scenario II in section 2.2 (see table 2). For the spray duration 10, 60 and 240 seconds respectively minute were chosen. The total amount released was kept constant. As was seen from the simulations in section 2.1 differences between BAMA and ConsExpo models were very small for 0.5 µm particles. Using these particles in a simulation of finite spray duration will demonstrate the difference between both models due to this assumption on spray or release duration only.

Results

Results are shown in figure 3. As anticipated, only in the initial phase, during spraying of the product, a difference between both models can be observed. In this phase, the BAMA tool provides a higher estimate of the exposure than the ConsExpo model. The BAMA model predictions in this initial phase are not expected to be very realistic. The assumption of immediate release is not accurate when the initial concentrations are considered. The concentrations during use of the spray may be relevant in cases where acute exposures (for example, peak exposures) are estimated. In these cases the ConsExpo model is expected to give more realistic results. The effect of the BAMA model assumption of immediate release is of less consequence when modelling longer time exposures (e.g. semi-chronic or chronic exposure) and the difference between BAMA and ConsExpo become insignificant. From this it is concluded that the BAMA tool is less appropriate for estimation of acute, short term exposures (on time scale of the product use).

17 0.00 0.05 0.10 0.15 0.0 0.1 0.2 0.3 0.4 0.5

Figure 3. Comparison of the ConsExpo spray model for particles with diameter 0.5 µm including the effect of finite spray duration with the BAMA indoor air model. The spray durations have been chosen as 10, 60, 240 seconds.

Air concentration including finite spray duration in ConsExpo vs BAMA model

Time (hr) Air concentration (mg/m3) ConsExpo Tspray: 10s BAMA ConsExpo Tspray: 60s ConsExpo Tspray: 240s

2.3

Adjusting the BAMA tool to account for particle size

distribution

The BAMA manual acknowledges the fact that the tool will generally over predict exposures for aerosol particles released from sprays. It is therefore recommended to incorporate information on the particle size distribution of the spray product in an assessment of exposure by including only the fraction of particulate matter with a diameter smaller than 10 µm. Conventionally, particles with (aerodynamic) diameters smaller than 10 µm are considered to be respirable (CEN, 1993), that is, have a potential to reach the lower regions of the respiratory tract (alveoli), from where uptake over the lung-blood barrier may take place. However, particulate matter with an aerodynamic diameter up to 100 µm will still be inhalable. Particles of these sizes will usually be removed by cillary clearing, which leads to oral exposure. Neglecting particles with sizes >10 µm as the BAMA manual suggests could very well lead to an underestimation of (oral) exposure.

For completeness simulations of exposure for two different types of sprays including information on the particle size distribution are described below.

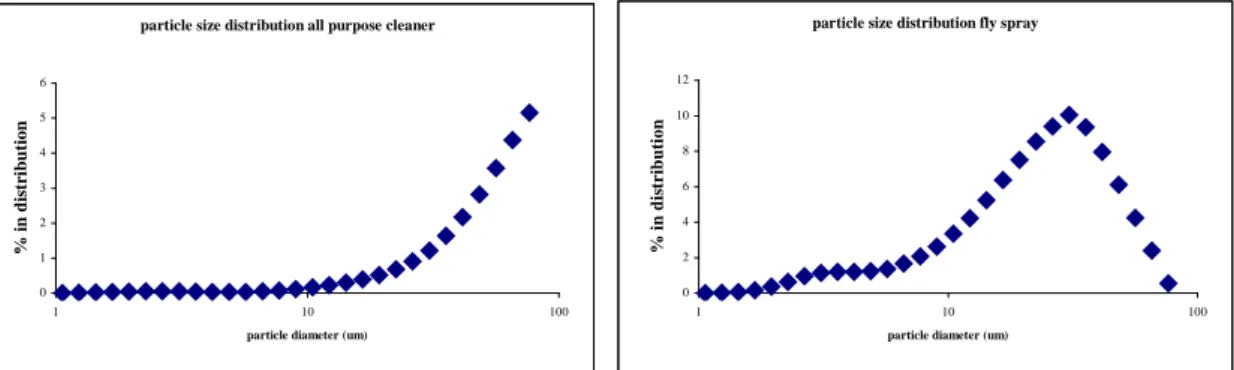

The products include a fly spray and an all-purpose cleaner. The information on the particles size was obtained in experiments with a Master Sizer (Delmaar, et al., 2009).

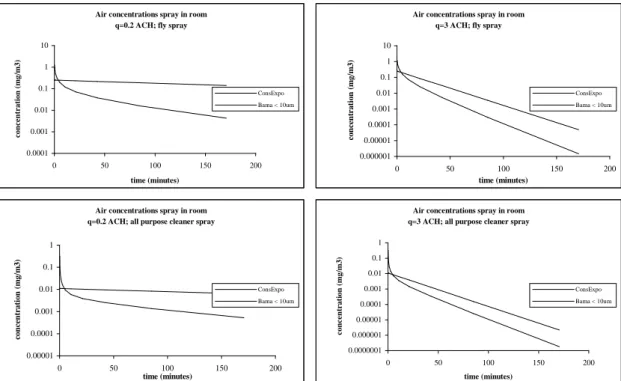

Using this information, ConsExpo and BAMA models were again used to model air concentrations in a small room of 20 m3 at two different ventilation rates: 0.2 and 3 ACH respectively. The total mass that was sprayed was assumed to be 2 gram of which only 1.5% was non-volatile (i.e. this fraction ends up in the aerosol, rest of the material was assumed to have evaporated directly after spraying). The mass density of the sprayed material was set at 1.5 g/cm3.

The particle size distributions are displayed in figure 4. In figure 5 the results of simulations using BAMA and ConsExpo models are presented.

It is seen from these simulations that, in all the presented cases, the BAMA model tends to predict lower concentrations than the ConsExpo model for the initial stages of exposure, but predicts significantly higher (one order of magnitude or more) exposures for longer times. Higher ventilation reduces somewhat the discrepancy between the two models, as was to be expected from earlier discussion. These two examples provide only an illustration of the kind of differences that remain between the modelling approaches when also information on the particle size distribution of the spray is included in the assessment. The presented results are by no means conclusive.

particle size distribution all purpose cleaner

0 1 2 3 4 5 6 1 10 100

particle diameter (um)

% in d is tr ib u tion

particle size distribution fly spray

0 2 4 6 8 10 12 1 10 100

particle diameter (um)

% in d is tr ib u tion

Figure 4. Particle size distributions of the two sprays used in the model simulations. The BAMA model is used with including only the fraction of the material with particle size smaller than 10 µm.

19

Air concentrations spray in room q=0.2 ACH; fly spray

0.0001 0.001 0.01 0.1 1 10 0 50 100 150 200 time (minutes) c on c e n tr at ion ( m g/ m 3) ConsExpo Bama < 10um

Air concentrations spray in room q=3 ACH; fly spray

0.000001 0.00001 0.0001 0.001 0.01 0.1 1 10 0 50 100 150 200 time (minutes) con ce n tr at ion (mg/ m3) ConsExpo Bama < 10um

Air concentrations spray in room q=0.2 ACH; all purpose cleaner spray

0.00001 0.0001 0.001 0.01 0.1 1 0 50 100 150 200 time (minutes) con ce n tr at ion (mg/ m3) ConsExpo Bama < 10um

Air concentrations spray in room q=3 ACH; all purpose cleaner spray

0.0000001 0.000001 0.00001 0.0001 0.001 0.01 0.1 1 0 50 100 150 200 time (minutes) c on c e n tr at ion ( m g/ m 3) ConsExpo Bama < 10um

Figure 5. Comparing BAMA and ConsExpo models taking into account a particle size distribution of the spray product. Simulated spray products included a fly spray and an all purpose cleaner. The BAMA model was run with the assumption recommended in the manual to only include material particles with diameter smaller than 10 µm. The ConsExpo model included all the sprayed material.

3

Conclusions & discussion

In this report a comparison between the ConsExpo spray model and the BAMA indoor air model for sprays was made. Both tools are intended for application in Chemical Safety Assessments under REACh for substances that are used in consumer spray products. A good understanding of the differences between theses tools is helpful in both the evaluation of Chemical Safety Assessments and as guidance on use of these tools.

The BAMA model is entirely equivalent to another ConsExpo model: the ‘instantaneous release’ model for vapours. This ConsExpo model is the preferred model to use when modelling exposure to volatile ingredients of spray products (i.e. for solvents and propellant gasses). For these ingredients, the ConsExpo and BAMA models are equivalent.

As the BAMA model does not consider spray characteristics such as particle size, the model seems to be more appropriate for volatile spray components such as propellants and solvents than for low volatile components that are released as aerosol. Comparison with the ConsExpo spray model demonstrated significant differences in model predictions between both models for particles larger than about 5 µm (depending also on other circumstances such as ventilation and room dimensions). The BAMA model ignores the removal of material from the air by gravitational deposition, which becomes an important removal process for larger particles. For these larger particles, the BAMA model predicts higher exposures than the ConsExpo spray model. Ignoring gravitational deposition does not seem a justified simplification when modelling consumer exposure to non-volatile particles in aerosol sprays. When using the BAMA tool in these instances, the model results should be interpreted as screening the upper boundaries of exposure rather than as realistic exposure estimates.

For smaller particles (smaller than about 1 µm, again depending also on other scenario parameters) the differences between ConsExpo and BAMA models become negligible. In this case ventilation will dominate the gravitational deposition as a removal process.

A second limitation on the BAMA model is that the model assumes immediate release of the sprayed material. The ConsExpo model, on the other hand, explicitly includes spraying with a finite spray duration. The difference between the BAMA and ConsExpo models may be significant during the application of the spray. For the longer time (average) air concentrations, however, the differences in both models as a result of this model assumption will usually be small. Assuming immediate release of a spray is an assumption that limits the applicability of the BAMA indoor air model to longer time exposures. The model is not well fit for estimating acute (peak concentration) exposures.

In summary, it can be concluded that the BAMA model is build on simpler principles. The simplified model structure leads in some cases to higher exposure estimates than the ConsExpo model. From this, it is concluded that the BAMA model are less suited for estimating short term, acute exposures and exposures to low volatile spray ingredients. For long term exposures to volatile ingredients, the ConsExpo and BAMA tools are equally suited.

On the use of these tools under REACh regulation it is concluded that the BAMA indoor air model is very well suited to perform first tier exposure evaluations, as the model requires comparatively little input data and the predicted outcomes will usually be very conservative. On the other hand, for more detailed exposure assessments, as may typically be required in higher tier exposure evaluations under REACh, the BAMA indoor air model will likely be too simplistic and the ConsExpo spray model provides a more suitable option.

The comparison in this report between ConsExpo and BAMA tools was focused on the physical/mathematical models. However, the BAMA tool offers an additional option, not present in the ConsExpo tool: the possibility to model multiple uses of the spray during a single exposure event. This

21

feature is absent in ConsExpo but would be a very valuable option to include as it is needed for more realistic exposure simulations.

References

Bremmer, H.J., Prud’homme de Lodder, L.C.H., van Engelen, J.G.M., 2006. General Fact Sheet. Limiting conditions and reliability, ventilation, room size, body surface area. RIVM Report 320104002. Comité Européen de Normalisation (CEN), 1993. Workplace Atmospheres- Size fraction definitions for

measurement of airborne particles. CEN Standard EN 481.

Delmaar, J.E., Park, M.V.D.Z., and Engelen, J.G.M. van, 2005. ConsExpo - Consumer Exposure and Uptake

Models -Program Manual. RIVM Report 320104004. Software available at www.consexpo.com.

Delmaar, J.E., and Bremmer H.J., 2009. The ConsExpo Spray Model. Modeling and experimental validation of the inhalation exposure of consumers to aerosols from spray cans and trigger sprays. RIVM

Report 320104005.

ECHA 2010. Guidance on information requirements and chemical safety assessment. Chapter R.15: Consumer exposure estimation.

Hinds, W.C., 1982. Aerosol Technology Properties Behavior, and Measurement of Airborne Particles. New York: Wiley-Interscience.

Rowley, J., 2005. Measurements of the dispersal of aerosol sprays in a room and comparison to a simple decay model. J. Environ. Monit., 7, pp. 960-963.