FEASIBILITY STUDY OF GROWING

HOPS IN ARKANSAS’ CLIMATE:

CHEMICAL AND SENSORY ANALYSIS

OF FIRST YEAR GROWN HOPS

Van Damme Arnout

Student number: 01606896Promotors: Dr. Renee Threlfall, Prof. Dr. ir. Jessika De Clippeleer,

A dissertation submitted to Ghent University in partial fulfilment of the requirements for the degree of Master of Science in the Biochemical Engineering Technology

FEASIBILITY STUDY OF GROWING

HOPS IN ARKANSAS’ CLIMATE:

CHEMICAL AND SENSORY ANALYSIS

OF FIRST YEAR GROWN HOPS

Word count: 19841

Van Damme Arnout

Student number: 01606896Promotors: Dr. Renee Threlfall, Prof. Dr. ir. Jessika De Clippeleer,

A dissertation submitted to Ghent University in partial fulfilment of the requirements for the degree of master of science in the biochemical engineering technology

Copyright protection

The author and promotor give the permission to use this thesis for consultation and to copy parts of it for personal use. Every other use is subject to the copyright laws, more specifically the source must be extensively specified when using the results from this thesis.

23/05/2020

Author Promotors

Van Damme Arnout Dr. Renee Threlfall

Preface

The study concerning the feasibility of growing hops in the U.S.A. state of Arkansas was initiated during the fall of 2018 by Drs. Jackie Lee, Amanda McWhirt, and Renee Threllfall. This project was supported by a grant from the Arkansas Department of Agriculture’s Specialty Crop Block Grant Program.

Writing this thesis was quite an experience considering the circumstances. From going all by myself to Arkansas and working in a new environment, to being confronted with the covid-19 pandemic and having to stay in the same environment facing new challenges. Of course there are a few persons who I want to thank, without whom this experience would not have been possible. First of all, I would like to thank my promotors. Dr. Renee Threlfall for giving me the opportunity to work together at this interesting study at the University of Arkansas (UofA), and for all the help that I received during my time in Fayetteville, Arkansas, as well as after my departure back to Belgium. Prof. Dr. ir. Jessika De Clippeleer for her expertise regarding hops and brewing science, and the support during my time in Ghent. Thank you for helping me with my numerous questions and for making me a better researcher.

I also want to express my gratitude to the whole team of the university of Arkansas that was part of this study, in particular Dr. Cindy Brownmiller for all her help in the lab and her laudable knowledge of every piece of equipment and every procedure. Cindy, you saved me countless times. James McLellan for being my partner during this research. It was great working with you, James. Also, a big thank you to Sarah Mayfield and Herbie Evans for all their help during the analyses and for making me feel at home in the United States. Thank you to my roommate Tad Beekman for the warm welcome and the company during my time in Fayetteville. Without you Tad, and all the friends I made thanks to you, my time there would have been much tougher. In addition, I would also like to thank my parents for giving me the opportunity to go abroad. Thanks for the support and advice throughout this journey. I could not have done this without your help. Last but not least, thanks to my girlfriend Marthe, my sister and friends both in Arkansas and Ghent. Without you, writing this thesis would be even more challenging than facing whichever pandemic.

Preamble

The original goal of this thesis was to evaluate the feasibility of hop growth in Arkansas, U.S.A., using data of first year grown hops. Because harvest and laboratory analyses were performed in the summer of 2019, no data loss was experienced due to measures against the global pandemic of Covid-19. Regarding data collection or reprocessing results, no reorientation was made for this master thesis from what was originally planned.

This preamble was drawn up in consultation between the student and promotors and approved by both.

Abstract

Hops plants (Humulus lupulus L.) are grown worldwide and produce hops cones used in beer for taste, and aroma. Since the local, craft-brewing industry is expanding in the state of Arkansas in the United States, evaluating hops as a potential crop could supply local brewers. The project team from the University of Arkansas System Division of Agriculture evaluated six hops cultivars (Cascade, Cashmere, Centennial, Crystal, Nugget, and Zeus) to assess growth in 2019. In addition, chemical attributes (moisture content and alpha-and beta-acids) were evaluated using American Society of Brewing Chemists (ASBC) HPLC and UV/VIS spectrophotometry procedures. Further, a descriptive sensory analysis with trained panelists evaluated hops aroma attributes. Four of the six cultivars had cone production with a total harvest weight of 13,9 kg. Zeus and Cascade had good plant survival, growth, and cone production in Arkansas. Hops cones from later harvests had higher total alpha-and beta-acid levels, as did pruning the hops plant later. Hops alpha-and beta-acid levels from HPLC-analysis were higher and more reliable than spectrophotometric analysis. Cascade, Cashmere, Crystal, and Zeus were the only cultivars that produced enough hops for chemical analysis. Zeus cultivars had an average total alpha acid level of 5.9% which was lower than expected. Sensory panelists found differences in hops aroma attributes including overall impact, terpene, thyme, overall pepper, and white pepper, but levels were low (0-6 of 15 points). Arkansas has challenging humidity and temperature for hops production, but first year results show potential to produce hops with quality cones.

Keywords: hops, feasibility study, growth, cone production, alpha-acids, beta-acids, descriptive sensory analysis

Table of contents

Copyright protection 4

Preface 5

Preamble 6

Abstract I

Table of contents III

Abbreviation list VI

List of figures VII

List of tables IX

Introduction 1

1 Literature review 2

1.1 Historical overview of the use of hops 2

1.2 Occurence and botany 3

1.3 Regions of hops production 5

1.3.1 Global hop growing regions 5

1.3.2 The state of Arkansas for hop growth 6

1.4 Growth and harvest of hops 6

1.5 Post-harvest 8

1.6 Chemical composition of hops 9

1.6.1 Hop resins 9

1.6.2 Essential Oils 15

1.6.3 Polyphenols 15

1.7 Hop types and cultivars 16

1.8 Previous studies 18

1.9 Analysis techniques 19

1.9.1 Moisture content measurement 19

1.9.2 HPLC 19

2 Materials and methods 23

2.1 Establishing the hop yard 23

2.1.1 Cultivar study 23

2.1.2 Pruning study 23

2.2 Morphological evalutions 24

2.3 Cone harvest 24

2.4 Hops drying, packaging, and storing 25

2.5 Analysis decision making 26

2.6 Measuring hop quality attributes 26

2.6.1 Moisture content 26

2.6.2 Alpha-and beta acid analyis of hops by HPLC 27

2.6.3 Alpha-and beta-acid analyis of hops by UV/VIS spectrophotometry 29

2.7 Sensory analysis 30 2.8 Statistical analysis 32 2.8.1 Cultivar study 32 2.8.2 Pruning study 33 2.8.3 Sensory study 33 3 Results 34

3.1 General growth and survival of hop plants 34

3.2 Cultivar study 35

3.2.1 Harvest data 35

3.2.2 Chemical analysis averaged over harvest dates 37

3.2.3 Study per harvest date 40

3.2.4 Descriptive sensory analysis 41

3.3 Pruning study 42

3.3.1 Harvest data 42

3.3.2 Chemical analysis averaged over harvest dates 42

4 Discussion 45

4.1 Drying procedure 45

4.3 Cultivar study 48

4.3.1 Biological feasibility of hop growth in Arkansas 49

4.3.2 Arkansas climate for hop growth 49

4.3.3 Chemical evaluation of alpha-and beta-acid levels 51

4.4 Pruning study 53

4.5 Descriptive sensory analysis 54

5 Conclusion 56

6 Bibliography 57

A. Appendix 1: High Performance Liquid Chromatography standard calibration curves and raw data for individual alpha and beta acid-fractions with standard ICE-4. i B. Appendix 2: Pictures and visual images as support of the thesis iii

C. Appendix 3: Additional tables vii

D. Appendix 4:Additional graphs and visual representations of data. xii

Abbreviation list

Abbreviation Explanation %w/w °N °S °W ANOVA AR ASBC BBCH GC HPLC ICE-4 lb LC-MS/MS NASS ODS oz/ac qts/ac RP-HPLC Tukey-HSD test UA UV/VIS-spectrophotometry α-acids β-acids γ-fractionConcentration weight on weight Degrees North

Degrees South Degrees West

Analysis Of Variance Arkansas

American Society of Brewing Chemists

Biologische Bundesansalt, Bundessortenamt und Chemische Industrie

Gas Chromatography

High Performance Liquid Chromatography International Calibration Extract-4

Pound

Liquid Chromatography-Mass Spectrometry National Agriculture Statistics Service Octadecyl-silica

Ounce per acre Quarters per acre

Reversed Phase High Performance Liquid Chromatography

Tukey-Honest Significant Difference test University of Arkansas Ultraviolet/Visual- spectrophotometry alpha-acids beta-acids gamma-fraction

List of figures

Figure 1: Classification of the hop plant (Almaguer et al., 2014) ... 3

Figure 2: The hop plant: A: Hop bine growing around the twine of a trellis; B: Hops root and rhizomes (Williams, Roberts, Coley-Smith 1961); C: Hop cone components (Dodds, 2017) ... 4

Figure 3: Global hop-growing regions (U.S.A Hops 2016 Statistical Report) ... 5

Figure 4: Phenological development stages of hops (Rossbauer et al., 1995) ... 7

Figure 5: Floor drying of hops in kiln, air is blown from underneath to lower moisture level . 9 Figure 6: Classification and nomenclature of hop resins (Almaguer et al., 2014) ... 10

Figure 7: Structure of alpha-acid, the general frame of an alpha-acid on the right, the R chain determines the specific kind of alpha-acid (Almaguer et al., 2014) ... 10

Figure 8: Isomerization α acids (alphaacids) producing diastereomeric transand cisiso α -acids (Almaguer et al., 2014) ... 12

Figure 9: Structure of beta-acid, the general frame of a beta-acid on the right, the R chain determines the specific kind of beta-acid (Almaguer et al., 2014) ... 12

Figure 10: Results of Haseleu et al., (2009): A: Bitter intensity of different hop fractions after model wort boiling ; B: (I) HPLC chromatogram with beta-acids colupulone (1), lupulone (2), and adlupulone (3) , (II) chromatogram of purified colupulone (1) before wort boiling (III) chromatogram of purified colupulone after wort boiling ... 13

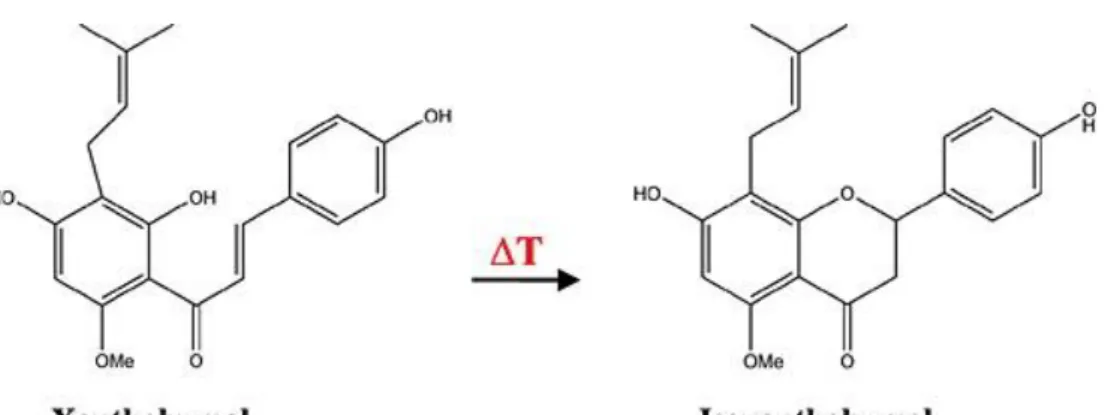

Figure 11: Structural formula of the major hard resins component xanthohumol and isomerisation reaction to isoxanthohumol (Almaguer et al., 2014) ... 14

Figure 12: Constituents of the hop polyphenol fraction (Almaguer et al.2014) ... 16

Figure 13: Principle of High Performance Liquid Chromatography (Knauer, 2019) ... 20

Figure 14: Principle ultraviolent (UV)-and visible light (VS) spectroscopy ... 20

Figure 15: Absorption spectra of lupulone and humulone complex in acidic (0.002N) and alkaline (0.002N) methanol (Alderton et al., 1954) ... 21

Figure 16: Zeus hops plant prior to pruning (A) and one week after pruning (B) at the Fruit Research Station in Clarksville, Arkansas (2019) ... 24

Figure 17: Hop were dried in a walk-in dehydrator (A) with fans and heater for hot air circulation (B) and dehumidifier to remove moisture (C) at the UA System Food Science Department, Fayetteville, Arkansas (2019) ... 25

Figure 19: Dried, ground Arkansas-grown hops placed in amber glass vials (A) and sensory panelist smelling hops aroma (B) for descriptive sensory evaluation at the UA System Sensory Science Center, Fayetteville (2019) ... 32 Figure 20:Pellets of commercial hops cultivars (before grinding) used for descriptive sensory panel orientation UA System Sensory Science Center, Fayetteville (2019)... 32 Figure 21: Assessment of hop plant growth and survival during the winter of 2018-2019 in Clarksville, AR ... 34 Figure 22: Total weight of hops cones harvested per plant for each cultivar, Clarksville, AR ... ... 36 Figure 23: Stacked bar harvest cone weight for each harvest date for each cultivar. Centennial is not visible on the graph because levels were low and Nugget plants were not included. .... 36 Figure 24: High Performance Liquid Chromatography analysis of total alpha-and beta-acid levels of hop cones from different cultivars grown in Clarksville, AR (2019) averaged over all harvest dates ... 38 Figure 25: High performance liquid chromatography of total alpha-acid results for two harvest periods of hops cultivars grown in Clarksville, AR (2019) ... 39 Figure 26: High performance liquid chromatography of total beta-acids results for two harvest periods of hops cultivars grown in Clarksville, AR (2019) ... 39 Figure 27: High performance liquid chromatography analysis of total alpha-and beta-acids of one Zeus plant (plant 3) for each harvest date ... 40 Figure 28: Descriptive sensory attributes scores of hops cultivars grown in Clarksville, AR (2019) ... 41 Figure 29: High performance liquid chromatography of total alpha and beta-acid levels of Cascade hops grown in Clarksville, AR (2019 with different pruning dates, early (April 15), mid (April 30), late (May 15) ... 43 Figure 30: Maximum and minimum Temperature in °C (yellow blocks); rainfall in mm (blue blocks) for Boone County airport close to Clarksville, AR (2019). (CustomWeather, 2020) .. 50 Figure 31: Maximum and minimum Temperature in °C (yellow blocks) ; rainfall in mm (blue blocks) for Yakima, Washington. (CustomWeather, 2020) ... 51

List of tables

Table 1: Levels of alpha and beta standards for the high performance liquid chromatography analysis ... 28 Table 2: Descriptive sensory lexicon of aroma from dried, ground hops grown in Arkansas (2019) 31

Table 3: Harvest data for cultivar study for hops grown in Clarksville, AR (2019) ... 35 Table 4: High performance liquid chromatography analysis of individual and total alpha and beta- acids levels of dried hops cones from hops grown in Clarksville, AR (2019) averaged over all harvest dates ... 37 Table 5: Harvest data for pruning study for Cascade plants grown in Clarksville, AR (2019) averaged per pruning treatment ... 42 Table 6: High performance liquid chromatography analysis of individual and total alpha and beta- acids levels per pruning treatment of Cascade hops grown in Clarksville, AR (2019 ) averaged over all harvest dates ... 43 Table 7: Moisture content, alpha and beta acids, and notes on hops from Zeus (plant 3) at the different harvest date ... 46 Table 8: Comparison between total alpha and beta acid levels of hops harvested in Clarksville, AR (2019) and previously reported data on the same cultivars ... 53

Introduction

Hops (Humulus lupulus L.) are used for the production of different types of beer, to provide bitterness and aromas. With the expansion of local and craft breweries in the state of Arkansas, U.S.A., this sparks the interest in evaluating whether hops could be a potential crop for Arkansas to supply that growing brewing market. This would offer brewers the opportunity to brew a local product using locally-grown hops or producing wet hopped beers with hop straight from the field. Arkansas’ climate has some challenges for a sustainable hop cultivation such as day length, a very hot and humid climate and heavy rainfall conditions which may limit yield or make the crop more conducive for diseases.

This preliminary study, which was on hops planted at the University of Arkansas (UA) System Division of Agriculture Fruit Research Station (Clarksville, U.S.A), investigated the production potential of hops cultivars. The production was evaluated in two separate studies, a cultivar study containing six cultivars (Cascade, Cashmere, Centennial, Crystal, Nugget, and Zeus) and a pruning study on Cascade with plants trimmed in spring on different dates. Initially, procedures were fine-tuned, not only regarding harvesting, drying and packaging of the hops, but also for chemical quality analysis. Once clear procedures were valid, data were generated from the first-year hop harvests allowing comparative analysis of growth rate and cone yield, and the effect of specific factors such as cultivar type and harvest date. Chemical quality analysis included moisture content and alpha (α)-and beta (β)-acid levels (%w/w) using both a High Performance Liquid Chromatography (HPLC) and a UV/VIS spectrophotometric method. The variation and the evolution of the alpha-and beta-acids were assessed for cultivars, pruning, harvest time and other known variables. The results of the two procedures for chemical analysis were compared with each other.

Hops were harvested once per week. In the cultivar study, levels of alpha-and beta-acids of a early harvest period were compared with those of later a harvest period for all cultivars. With a harvest period consisting of multiple harvest dates (multiple weeks). Additionally a comparison of alpha-and beta-acids for a single plant was done with data for six individual harvest dates. In this cultivar study, a descriptive sensory analysis was conducted with trained panelists who evaluated the aroma of the different dried hop cultivars. The pruning study compared harvest data and alpha-and beta-acid levels between plants that were pruned on different dates.

The objective of this study was to evaluate the feasibility of growing hops in Arkansas including the chemical and sensory attributes of the hops in the first year of production. These different studies provided a better view on the feasibility of hop growth in Arkansas and the quality of the produced hops. The new insights, including an evaluation of the methodology, will contribute to improve procedures and provide recommendations for future research.

1

Literature review

1.1 Historical overview of the use of hops

Hops (Humulus lupulus L.) plants grow wild or are cultivated in hops fields or yards. The plants and the flowers (or cones) produced have been used throughout history. One of the first mentions of hops was by Plinius when he described hops in his “Naturalis Historia” as a garden plant which grew between willow trees 'like a wolf between sheep’. Probably because of the fact that the plant tends to strangle the other plants and trees with its bines and roots. With the Latin translation of ‘wolf’ being ‘Lupus’, this gave origin to the name ‘Lupus salictarius’ which the Romans used. The actual name Humulus lupulus was derived from the latter (De Keukeleire &Verzele, 1991).

Hops in Europe were mentioned as early as the 8th and 9th century in abbeys, primarily recognized for medicinal purposes. They were used to help humans with tension and insomnia. A hop pillow for good sleep is a contemporary example of this attribute. Brewing with hops began on a large scale in Germany in the 12th and 13th century. In Flanders, it started in the 14th century. John the Fearless, Duke of Burgundy was an enthusiast of the use of hops in beer even though this was not common at the time. In the United states, commercial growing of hops started in the 19th century (Burgess, 1964) (Hornsey, 2007).

People initially did not use hops in the brewing process. The more traditional ways of brewing made use of aromatic herbs and grut to flavor beer. Grut is a combination of herbs that flavor and preserve the beer. Before the introduction of hops, breweries were subjected to a ‘flavoring licence’ called ‘Grutrecht’, named after the grut. Brewers were forced to buy grut for their brews from local rulers since brewing beer without grut was forbidden. When the practice of adding hops threatened the Grutrecht, local rulers in many regions reacted by forbidding their use. This prohibition lasted until after the 14th century (Cabras & Higgins, 2016). The introduction of hops represented an important innovation of monastic brewing. As time passed, hops were more accepted in the brewing culture until today where it is hard to find a beer made without hops. This ingredient is what distinguishes beer from other fermented beverages. Hops are suitable for the brewing process because of its contribution to the bitter taste and hoppy aroma of beer, but also has positive influences on mouthfeel, foam stability, microbial stability and wort clarification. Pale lager beers currently produced only use hops. Other spices and herbs are used for specific flavors in specialty beers but not for bittering. Hops are not only used in beer. They can also be used in tea which has natural sedative properties. Apart from beverages, the early roots of hops can be used in salads. The shoots of the hop plants contain fiber, which also makes them suitable for the production of rudimentary paper.

1.2 Occurence and botany

The hop plant (Humulus lupulus L.) is a species of the Cannabaceae or hemp family. An overview of this family can be seen in Figure 1. The hemp family only contains four species. Next to Humulus another genus in this family is Cannabis which contains Cannabis sativa, also known as marijuana. Humulus contains two main species, Humulus lupulus L. also known as the commonly used hops and the Humulus japonicus or Japanese hops. A third species, Humulus yannanensis was described in 1936, but was considered the same as H. lupulus because little was known of the species grown in high, difficult to reach places in the Yunnan province of Southern China. Only years later, it was classified as an independent species (Small, 1978).

Figure 1: Classification of the hop plant (Almaguer et al., 2014)

H. lupulus is a perennial plant. The plant can live for more than two years and up to 20 years (Almaguer et al., 2014). It is a dioecious plant which means that the male and female reproduction organs cannot both be present on the same organism. As unisexual male or female flowers grow on separate plants, male and female species can undergo xenogamy or cross pollination. Hops are herbaceous climbing plants, called bine plants. The bine (which can be seen in Figure 2-A) is one of the major components of the plant, together with the roots and rhizomes, the leaves, and the flowers (hop cones).

The storage organ of the plant is called the rhizome crown. A rhizome is the underground stem with buds and roots. The roots (Figure 2-B) can penetrate the soil to a depth of 4.5 meters or more. A bine plant is different from a vine plant like grapes. Bines are twining vines and have stiff downward facing hairs that act like hooks for climbing. The bines provide the necessary photosynthetic capacity for flowering. New shoots arise in spring emerging from dormant buds on the rhizomes. This starts just below the soil surface, but the bines grow each year to be about eight meters long. Lateral arms can be formed at the bine nodes. In the fall, the plant dies back to its crown (Dodds, 2017).

The flowers of the plant are called hop cones (Figure 2-C). These are the parts of the plant used in brewing. The cone or strobilus consists of bracts and bracteoles. These are petal-like structures and are shaped around a central axis, also called a strig. Only the bracteoles contain the lupulin glands which are formed as the plant ripens. These can be recognized as small, yellow glands that produce lupulin, a resinous yellow sticky powder, highly important for the beer flavor. The lupulin contains alpha-and beta-acids as well as essential oils. The glands are formed as the hop ripens (Garetz, 1994). Only female plants produce lupulin. W. Ives (1821) discussed the chemical, economical and medical virtues of the common hops, calling the yellow substance of the “nectaria” of the female plant ‘lupulin’ and noticing the subtle aroma (Partington & Newton, 1821).

Figure 2: The hop plant: A: Hop bine growing around the twine of a trellis; B: Hops root and rhizomes (Williams, Roberts, Coley-Smith 1961); C: Hop cone components (Dodds, 2017)

The female hop plants are commercially cultivated, since those hops are used for bittering the beer (Roberts & Wilson, 2006). Female cones obtain more than 10,000 lupulin glands, while male cones have almost no lupulin glands. Growing male plants is strictly controlled and even forbidden by law because they could fertilize a female plant which if fertilized will produce seeds in the hop cone. These seeds are located in the bracteoles, like the lupulin glands, but are considered undesirable in the brewing process. Beer brewed with seedless hops was preferred over that brewed with seeded hops (Zattler & Krauss, 1970). The oil of hop seeds can be the cause of unsavory beer flavors (Harrison, 1971). It was stated that this was more noticeable when the beer was six weeks old because of the oxidation of the seed fatty acids. These seed fatty acids can also have a negative effect on the beers foam stability. This is why male hops are typically removed from hops fields. Another reason why male hops are avoided is because female hops are richer in essential oils needed for brewing. However, male plants are used in hop breeding programs for cultivar development (Almaguer et al., 2014).

1.3 Regions of hops production

1.3.1 Global hop growing regions

Hops require optimal growth conditions that include length of exposure to daylight, temperature, rainfall, and soil fertility. Hops are photoperiod-sensitive plants. Photoperiodism refers to a plant’s tendency to grow and flower in response to day (or night) length. It is most productive when day length ensures good vegetative growth and flower induction. Day length is a function of latitude, which is a key factor in hop growth (Dodds, 2017). Hops are mostly grown in moderate climate zones. Areas with wild growth and controlled planted growth are situated in the Northern Hemisphere between latitudes 33°N and 55°N (Figure 3). The most successful hops harvests are achieved in periods with high levels of rainfall and sunlight. The soil should not contain high levels of alkalinity or salinity (De Keukeleire & Verzele, 1991). In 2018, the harvest volume of hops worldwide was 118 410 metric tons. In the United States of America (U.S.A.) the production value was stated at 538,44 million U.S. dollars in 2018 (Shahbandeh, 2019) (Conway, 2019).

In the northern hemisphere, important hop-growing countries are Germany and the U.S.A., that represent respectively 30% and 20% of the total world production. Hops are also produced in the Southern hemisphere centered around Australia and New Zealand at latitudes 35°S and 40°S. Popular Southern hops are ‘Nelson Sauvin’ and ‘Galaxy’. Even in George, South Africa, which is outside the generally accepted optimum latitude range there is a hop industry with cultivars like ‘Southern promise’ and ‘Southern brewer’ adapted to this latitude (Dodds, 2017).

1.3.2 The state of Arkansas for hop growth

In the U.S.A. most of the hops is produced in the Northwest region. The National Agriculture Statistics Service (NASS 2019) of the United States Department of Agriculture (USDA), identified three states (Idaho, Oregon, and Washington) responsible for the majority (97%) of hops cones produced in the United States. Since the demand for local U.S.A. hops is high, and supply is often limited, there have been efforts to expand hops production to other states. Since hops are a key ingredient for craft beer production, there is interest in growing hops in Arkansas. Arkansas is a state in the southern region of the U.S.A. that borders Missouri in the north, Tennessee and Mississippi to the east, Louisiana to the south, Texas to the southwest and Oklahoma to the west. Arkansas is positioned geographically between 36.5°N-33°N and between 94.4°W-91.2 °W. This means that the northern part of Arkansas is on the lowest point regarding northern latitude were the daylength would be long enough to grow hops (Figure 3). The longest day in Arkansas has an average amount of sunlight for approximately 14h25min at the summer solstice. On the winter solstice, the shortest day is approximately 9h53min. At 55°N, the other border of the optimal growth region, the maximal daylength is 17h33min and the minimal daylength 7h (CustomWeather, 2020).

1.4 Growth and harvest of hops

As mentioned earlier, hops start to grow in spring. The best time of the year to plant hops is when the risk of frost is over, yet in the northern hemisphere no later than May. During the first year of growth, the plants invest energy in achieving root depth. This is why the hops plants do not grow as vigorously the first year as they will the following years. Much of the hop plant’s success depends on the soil conditions and fertility. Hop plants grow best on a well-drained soil that has a good structure. Keeping the soil moist, but not saturated is important for the growth. The hop plant prefers a pH of 6.0-8.0. Pre-plant soil tests are used to determine if growers need to fertilize. As for all crops, hops need nitrogen, potassium, and phosphate. A nitrogen soil concentration of 85 kg per hectare is recommended. The application of nitrogen is spread over spring and summer to avoid excess concentrations that could cause burns by dehydration of the roots (Gingrich et al., 1994).

Hop cultivation needs infrastructure. Commonly used installations for hops production are trellises for supporting the plant’s growth. The structure needs to be strong but also facilitate easy harvesting. The use of vertical ropes/twines to the trellis are common. The bines of the plant will climb up the twine and hook to the trellis. Hops are planted as rhizome cuttings or rooted cuttings from the previous spring. After planting, it is important to manage soil moisture, nutrition, and possible pests or weeds. Irrigation systems, like drip irrigation can be water efficient and should be ready from day one after planting. Weed management is important because the competition for water and nutrients in the soil has to be reduced.

Chemical weed management is a cost-effective way of doing this, but herbicides regulations can be strict and vary by location. An herbicide, like Simazine (used in New South Wales, Australia) is pre-emergent and is applied soon after planting to reduce the emergence of new weeds. Other herbicides are broad spectrum and come in contact with actively growing plants. These management techniques can be used to create optimal conditions to grow hops (Dodds, 2017).

The German Biologische Bundesanstalt, Bundessortenamt und Chemische Industrie (BBCH)-scale for hops was developed in 1995 to identify the phenological development changes in the growth of a plant (Figure 4). According to this scale, the growth of hops consists of nine stages. 1: sprouting, 2: leave development, 3: elongation of bines, 4: formation of side shoots, 5: flower emergence, 6: flowering, 7: development of cones, 8: maturation of cones, and 9: entry into dormancy (Meier, 2001).

Figure 4: Phenological development stages of hops (Rossbauer et al., 1995)

Hops is a very fast-growing plant; it grows 3-4 m in June to 6-10 m in July-August. The female flowers or hop cones are fully developed in 2-3 weeks but at least three more weeks are necessary to increase the resin level in the lupulin glands. The flowers or cones are mostly

On the Southern hemisphere harvest takes place around March and April. Checking if a hop cone is ready for harvest can happen in multiple ways. Ideally, a daily analysis of alpha-acids level from the cones on the vines should determine the best harvest period. In practice, this is not always possible for small-scale hops growers. Most growers determine the cone ripeness by visual and aroma examination. Early-picked hops are green and smell fresh and grassy. The bitter acids (alpha-acids and beta-acids) and essential oil levels in these early stages are very low (De Keukeleire & Verzele, 1991). Later-picked hops can reach a stage where end-of-season oxidative deterioration has started. These hops have a higher essential oil composition and bitter potential, but the oils might oxidize when waiting too long before harvesting. But even though their alpha-acids are high, quality can be low. They can smell like sulfur, onion, or even garlic. Where early-picked hops are green, more ripe cones undergo a color change to yellowish or yellow/brown. The ripe cones feel papery when rubbing the hops in the palms of your hand. Growers experience with hops ripeness is key for these interpretations.

The moisture content of a cone can be an indication of when to harvest, ranging from 77-80% depending on the cultivar. Moisture content can be determined by a grower using a dehydrator, microwave, or oven (Darby et al., 2013). As hop cones mature, the percentage of moisture to green weight decreases by 1% every 4-7 days. Harvesting can be done by hand or by machines. For large-scale hops production, harvest machines are needed to reduce labor costs. For in-field picking, a machine strips the cones from the bines in the field. Afterwards, the cones are transferred to a shed for further processing of the hops. For in-shed picking, the whole bines are cut and transferred to the shed for the picking machine to remove the cones (Dodds, 2017).

1.5 Post-harvest

After harvest, hop cones need to dry for good storability and quality. Drying hops can be done in multiple ways. The most specialized way to dry hops is in a kiln (Figure 5). Warm air is blown through the hops until the moisture content drops to 8-10%. Temperatures between 50-70°C are used for this kiln application. In practice, the moisture content is reduced more than the required 8-10% because cooling reraises the moisture content. The hops are therefore initially dried to a moisture of 5-6% moisture. The cool-off after drying happens without moving the hops because in dry state, hops tend to lose lupulin. The drying procedure can affect the quality of hops. A yellow-brown colouring of the cone can occur. Burning sulfur in the drying gasstream can be done to prevent this color degradation. However, Picket et al. (1976) noted that this handling led to an increase in total sulfur content which can affect the aroma. Some growers dry hops in sheds or barns. Other options are available, such as a dehydrator or an oven. These can be used for smaller batches. Hop storage is done mostly by vacuum packaging in cooled rooms. The storage is also important to sustain the quality of hops (Dodds, 2017).

Figure 5: Floor drying of hops in kiln, air is blown from underneath to lower moisture level

1.6 Chemical composition of hops

The lupulin glands of the female hop cones secrete the lupulin powder that contains the resins and essential oils (Van Cleemput et al., 2009). The resins and the essential oils have components that impart the unique characteristics in beer production.

1.6.1 Hop resins

The hops resins are categorized by their solubility in different solvents with the soft resins’ and hard resins’ ability to dissolve in hexane. In the early stages of hops-research, the resins were classified as α (alpha)-, β (beta)- and γ (gamma)-fractions. In 1957, the European Brewery Convention (EBC) and the American Society of Brewing Chemists (ASBC) agreed to a fixed nomenclature which was reviewed in 1967. The γ-fraction was officially renamed ‘hard resins’. The nomenclature and composition of the hop resins is shown in Figure 6 (Almaguer et al., 2014). The nomenclature of hop resin components has been firmly established since 1967, including the following definitions (Briggs et al, 2004):

Non–specific fractions

-

Total resins. The part of the hop constituents that is characterized by solubility both in coldmethanol and diethyl ether (mainly hard resins, uncharacterized soft resins, alpha-acids and beta-acids)

-

Total soft resins. The fraction of the total resins that is characterized by solubility in hexane(mainly alpha-acids, beta-acids and uncharacterized soft resins)

-

Hard resins. The fraction of total resins that is insoluble in hexane.-

Beta fraction. Total soft resins minus the alpha-acids-

Uncharacterized soft resins. The portion of the total soft resins that has not beenSpecific compounds

-

Alpha-acids. Mainly humulone, cohumulone and adhumulone.-

Beta-acids. Mainly lupulone, colupulone and adlupuloneFigure 6: Classification and nomenclature of hop resins (Almaguer et al., 2014)

1.6.1.1 Alpha-acids

The alpha-acids (also called humulones) are part of the soft resins and the most important elements of the hop resins and in the brewing process. Although the term ‘resin’ can be misguiding considering the fact that the main constituents of this soft-resin group (alpha-and beta-acids) are crystalline and not resinous by nature.

Figure 7: Structure of alpha-acid, the general frame of an alpha-acid on the right, the R chain determines the specific kind of alpha-acid (Almaguer et al., 2014)

The structure of an alpha-acid (Figure 7) was first determined by De Keukeleire and Verzele in 1969 using spectrophotometric and chiroptical techniques. The general structure of an alpha-acid contains a side chain ‘R’ which can vary depending on the specific kind of alpha-alpha-acid. Cohumulone, n-humulone and adhumulone are the most common alpha-acids. Other less abundant alpha-acids are posthumulone and prehumulone. N-humulone which is also called just humulone has the empirical formula C21H30O5 with a melting point of 70-72°C. It represents

35-70% of the hop alpha-acids. Cohumulone (C20H28O5) and adhumulone (C21H30O5) represent

respectively 20-65% and 10-15%. The percentages of humulone and cohumulone are cultivar dependent, while the percentage of adhumulone is fairly constant (De Keukeleire & Verzele, 1970).

In the brewing process, hops are added at the wort boiling step. For brewing, alpha-acids are beneficial for foam stability and preservation of the beer due to their bacteriostatic activity. The interference of the prenyl side chain - which is characteristic for each hop acid - with the function of the cell plasma membrane results in the inhibition of the growth of Gram-positive bacteria (De Keukeleire, 2000). They also suppress gushing (this is the occurrence of vigorous overflowing of beer upon opening the bottle or can).

The acids do not taste bitter initially. In the wort boiling process of brewing, the alpha-acids undergo an isomerization to produce iso-alpha-alpha-acids because of the high temperatures in the wort kettle (Figure 8). This temperature is a determining factor in the rate of conversion of alpha-acids to iso-alpha-acids. The solubility of alpha-acids increases with increasing temperature (Malowicki & Shellhammer, 2005). Iso-alpha-acids are named similar to the original alpha-acids: isohumulone, isocohumulone and isoadhumulone. The alpha-acids can occur as diastereoisomers in their cis and trans forms of the latter. Where alpha-acids do not taste bitter on their own, iso-alpha acids are the biggest contributors to the bitter flavor in beer (Almaguer et al., 2014). Iso-alpha-acids are present in a range of 15 mg/L in some American lager beers and to 100 mg/L in bitter English ales. The very bitter taste of these iso-alpha-acids is often mitigated by complexation with residual sugars present in beer. The High Performance Liquid Chromatography (HPLC)-technique is used frequently to evaluate hop bitter acids and iso-alpha-acids. In a study from De Keukeleire (2000) a reversed phase HPLC (RP-HPLC) separation of the isohumulones in a lager beer found the six major iso-alpha-acids (isohumulone and trans-(isohumulone, isocohumulone and trans-isocohumulone, cis-isoadhumulone and trans-cis-isoadhumulone). Where cis-and-trans-isocohumulone had the shortest retention time and trans-and-cis-isoadhumulone the longest.

Figure 8: Isomerization α -acids (alpha-acids) producing diastereomeric trans-and cis-iso- α -acids (Almaguer et al., 2014)

Separation of alpha-acids and beta-acids can be achieved by precipitation after adding lead(II) acetate. The resulting yellow-colored lead salts are fairly stable and not very sensitive to deterioration. Beta-acids (Figure 9) cannot form this precipitation because the formation must involve the tertiary alcohol function which is absent in beta-acids. The exact mechanism of the precipitation is not yet known. The three most import alpha-acids can be separated to study each compound individually. Humulone can be separated from a mixture by complexation with 1,2 -phenylene-diamine followed by repeated crystallization. Isolation of cohumulone and adhumulone can be achieved by preparative HPLC (Van Cleemput, et al., 2009).

1.6.1.2 Beta-acids

The beta-fraction of the soft resins consists of beta-acids (also called lupulones) and uncharacterized soft resins. Beta-acids are not as well studied as the alpha-acids but have the same relation of compounds as the alpha-acids. For this reason, they are named analogously. The three most important beta-acids colupulone (molecular formula: C25H36O4), lupulone

(C26H38O4), and adlupulone (C26H38O4) are shown in Figure 9.

Figure 9: Structure of beta-acid, the general frame of a beta-acid on the right, the R chain determines the specific kind of beta-acid (Almaguer et al., 2014)

Beta-acids are less acidic then alpha-acids, because the tertiary alcohol function at C-6 is replaced by an extra prenyl side chain. Beta-acids are hard to dissolve in water. Regarding bitterness potential, beta-acids are less important than the alpha-acids, but they contribute to the bitter flavor. In the brewing process they do not undergo isomerization like alpha-acids, however they are sensitive to oxidation. This can be initiated by air, and a particular oxidation reaction can lead to the formation of hulupulones. These are stable components that have a noticeable bitter taste present in beer. Bitter tasting beta-acids oxidation products have been found by Haseleu et al. (2009) under wort-boiling conditions. For this study, colupulone was isolated from a hop extract using RP-HPLC. This could be treated under wort-boiling conditions and afterwards investigated for bitter tasting degradation products. First the hop extract underwent a preparative fractionation using column chromatography. Hereby nine fractions were obtained by flushing the column with different gradients of a mixture of acetonitrile and water. The fractions were boiled for 1 hr at 110°C, to simulate the wort boiling in the brewing process. A sensory panel was used to evaluate the bitter intensities of these fractions as compared to the bitter tasting fractions of the hop extracts before boiling (Figure 10-A). According to this panel, wort boiling increased the bitter intensity of certain fractions. With the wort boiling, the alpha-acids were isomerized into the more bitter tasting iso-alpha-acids. These had the highest bitter intensities (fractions V-VII in Figure 10-A) However, in fraction VIII the pure beta-acids were found using RP-HPLC. This fraction also showed an increase in bitter intensity after wort boiling. Looking at Figure 10-B one can see in the first row I the beta-acids colupulone (1), lupulone (2) and adlupulone (3). In row II the absorption results of isolated and purified colupulone can be seen before wort boiling. Row III gives the results after boiling showing new formed degradation products after 50-60 minutes. Further investigation showed that it were these degradation products that provided a bitter taste. This shows that beta-acids do contribute to a bittering taste despite not undergoing an isomerization reaction like alpha- acids.(Haseleu et al., 2009)

Figure 10: Results of Haseleu et al., (2009): A: Bitter intensity of different hop fractions after model wort boiling ; B: (I) HPLC chromatogram with beta-acids colupulone (1), lupulone (2), and adlupulone (3) , (II) chromatogram of purified

1.6.1.3 Hard-resins

The major hard resin component is xanthohumol (Figure 11). This is part of the beta-fraction which is the largest fraction of the hard resins. Xanthohumol has been found to be a cancer chemoprotective agent. It can inhibit the metabolic activation of procarcinogens, and also prevent tumor growth via inhibiting inflammatory signals of angiogenesis at early stages. Derivatives of this compound like isoxanthohumol (an isomerization product) have been proposed to contribute to the bitter taste of beers by coactivating certain human bitter-taste receptors (Dresel et al., 2015). In hops the level of xanthohumol is higher than the level of isoxanthohumol, in beer however the level of xanthohumol is lower due to thermal isomerization during the brewing process. Isoxanthohumol also shows anticarcinogenic properties by inhibiting enzymes that mediate the metabolic activation of many chemical carcinogens (Stevens & Page, 2004) (Sohrabvandi et al. 2012).

Figure 11: Structural formula of the major hard resins component xanthohumol and isomerisation reaction to isoxanthohumol (Almaguer et al., 2014)

The hard resins are soluble in methanol like soft resins but insoluble in hexane. There is a difference between native hard resins present in hops in the earlier stages of development and hard resins formed by autoxidation of soft resins (mainly alpha-and beta-acids). This spontaneous oxidation can arise throughout kilning or storage of the hops. Research by Burton and Stevens (1965) stated that the percentage of soft resin falls while hard resins increase during the aging of hops throughout storage. An independent study also mentioned the increase of the hard resins content by temperature, but the total resin content stayed the same (Skinner, Hildebrand, & Clarke, 1977). During storage, oxidation of alpha- and beta-acids leads to the formation of flavor components. At first these acids remain soft resins, but gradually they can transform over time into hard resins. Changes from alpha-acids and beta-acids thus gives the formation of alpha-hard resins and beta-hard resins. The major difference between alpha-hard resins and beta-hard resins is analogue to the soft resins their ability to dissolve in certain mixtures. Like the soft resins, alpha-hard resins can form an insoluble lead salt in a lead acetate solution, while beta-hard resins are not capable of accomplishing this.

1.6.2 Essential Oils

Essential oils are secondary metabolites secreted in the lupulin glands of the hop cones. The hop oil fraction is volatile. The volatile compounds are important because they give hops their characteristic odor and aroma. Essential oils are valuable to brewers because they have a high contribution to beer flavor. Using capillary gas chromatography in the early 2000’s showed 440 chemically characterized compounds in the hop oil fraction of hops. Later with the use of comprehensive multidimensional gas chromatography (GC × GC) there was shown that there might be over 1000 compounds in the hop oil fraction. Essential oils make up between 0.5-3% of the gross composition of the dried hop cone (Almaguer et al., 2014).

Three main groups can be identified in the hop essential oils; the hydrocarbons, the oxygenated compounds and the sulfur-containing compounds. The amounts of these groups can vary according to hop cultivar and age. This was discussed in the study of Likens & Nickerson (1967). In this study, the hop essential oil fraction of different hop cultivars was compared and stated that the oil fraction was fairly constant per cultivar regardless of the growing location. This was later contradicted by Benitez et al. (1997) that stated that geographical location, climate, harvest time and agronomical factors could impact hop oil composition.

In the brewing process, hops with different odors and aromas are used. These differences in sensory attributes can be attributed to the composition of their essential oil. To minimize evaporation of essential oils and retain aroma compounds, hops can be added at the end of wort boiling (late hopping) or even to the whirlpool-stage of the brewing process. A beer can also be dry-hopped, this is when the hops are added to the fermenter, which provides more aroma to the beer because volatiles evaporate less than during the wort boiling process. The relation of alpha-acids to oil is important because brewers primarily add hops to the kettle based on their alpha-acids to achieve the desired bitterness. Hop derived-compounds such as geraniol and linalool as well as different degradation products of humulene and many others are involved in the final total flavor of beer. Especially the levels of geraniol and linalool in beer are strongly dependent on which hop cultivar was used in the brewing. Geraniol and linalool are terpene alcohols occurring in the essential oils of several aromatic plants (Dresel et al., 2015). In different studies also some correlations were found between humulene (a component of the hydrocarbon fraction of hop oils) and the spicy taste, however, the correlation does not always mean a cause and effect relationship (Eyres & Dufour, 2009).

1.6.3 Polyphenols

Polyphenols are the third group of components valuable for brewing. As secondary metabolites, the level of hop polyphenols is cultivar dependent. Polyphenols share a common structural element: an aromatic ring with at least two hydroxyl groups. The hops polyphenols can be categorized in four major groups: the flavonols, flavan-3-ols, phenolic carboxylic acids and the remaining fraction which contains the reservatrols and others (Figure 12).

In general, bittering hops contain a lower amount of low molecular weight polyphenols than aroma hops. Storage conditions have an impact on the degradation of polyphenols. The degradation of polyphenols is less compared to alpha-and beta-acids degradation. In a study of Mikyška and Krofta (2012) it was shown that polyphenols started to decay after about six months and after 12 months aged hops lost about 30-40% of polyphenols and 20-30% of flavonoids (including flavonols and flavan-3-ols). This could be caused by oxidation at sample packing.

Figure 12: Constituents of the hop polyphenol fraction (Almaguer et al.2014)

Polyphenols act as natural antioxidants and are therefore believed to be beneficial for human health. They contribute to the taste stability and influence the shelf-life of bottled beers. Low‐ molecular‐weight polyphenols are natural antioxidants and improve beer flavor stability. Higher‐molecular‐weight polyphenols contribute to the color of beer and to haze formation (Almaguer et al. 2014).

1.7 Hop types and cultivars

Knowledge about the presence and concentration of certain compounds is essential for brewers to determine if the hops is suitable for the beer they want to brew. Different kinds of hops exist. Hops can be classified as “aroma hops” and “bitter hops”. The bitter hops have a higher alpha-acids content (7-10% w/w), a lower beta-alpha-acids concentration and a hop oil content in the range of 1.0-2.0% w/w. Bitter hops have a higher bitter potential but have a less prominent aroma. Examples are Brewers Gold, Challenger, Premiant or Northern Brewer (Krofta, 2003). These are used on a large-scale as addition in the wort boiling step for the bitter taste of beer. Aroma hops have a lower alpha-acids (4-7% w/w) content but have a better aroma. The beta-acids concentration is in the range of 2-8% w/w. Bitter hops are added early in the process to impart bitterness, as they release more alpha acids the longer they boil. Aroma hops are usually used at the end of the brewing process. These hops are used to finetune the sensory profile of the beer. Another group is the “super hops” or the “high hops”. These have an alpha-acids concentration higher than 10% w/w with hop oil components in the range of 1.5-3.0% w/w. Their aroma is considered better than bitter hops, but less than aroma hops (Schönberger & Kostelecky, 2011).

There are many hop cultivars grown world-wide. Popular European hops are noble hops, these classic European varieties have been cultivated in specific regions for hundreds of years. The four noble cultivars are Hallertauer Mittelfrüh, Tettnang, Spalt, and Saaz. Popular hops in the United States are Cascade, Centennial, Chinook and Citra. In 2018, the average price of hops in the U.S.A. was 5.46 U.S. dollars per pound, which is approximately 11 euros per kilogram (Shahbandeh, 2019). Through hop breeding programs there are new cultivars of hops that have been produced. In the book “For The Love of Hops” by Hieronymus (2012), there are fact sheets for different varieties of hops that are grown in the United States. The hops cultivars listed below were used in this thesis.

Cascade: Since 1972, Cascade is one of the most widely used hops in the U.S.A.. It is an

extremely versatile hop variety that can be used at any time in the brewing process and in numerous types of beers. The alpha-acids range from 4.5-7% w/w and beta-acids range from 4.0-9.0% w/w. It gives a smooth bitterness and slight citrus aroma to the beer.

Cashmere: This is a relatively new hop variety created in 2013 by Washington State

University. It is mostly used in single-hopped pale ales for tropical fruit (lemon, lime, peach) and slightly herbal (lemongrass) aroma and flavor. The total alpha-acids and beta-acids levels are respectively 7.7-9.1% w/w and 6.1-7.1% w/w.

Centennial: Originated in the U.S.A. in 1990 as a mix of Brewers Gold, Fuggles, East Kent

Golding and Bavarian. It is primarily used as bitter hops but is also known as dual-purpose hops. Dual purpose hops are hops that can be used for both bittering purposes earlier in the brewing process as later in the brewing process for the aroma. It is used in Pale Ale, Amber, IPA’s and described as slightly more bitter hops. The alpha-acids levels are 9.5-11.0% w/w and the beta acids levels 3.5-4.5% w/w, and it maintains about 60% acids after 6 months in the freezer.

Crystal: Crystal was released by the USDA as a new breeding line in 1993 with the help of

varieties like Mt. Hood, Cascade, Brewers Gold and Hallertau Hersbrucker. With its alpha-acids concentration of 3.5-6.0% w/w and beta-alpha-acids concentration of 4.5-6.5% w/w, it is a mild floral aroma hops with aromas of cinnamon and black pepper combined with grassy and floral flavors.

Nugget: This cultivar was bred by the USDA in 1982. These hops are used as dual-purpose

hops in Imperial beers, IPA’s, Pale ales, stouts and Barley Wines. It is described as spicy and herbal with a very clean strong bitterness. The alpha-acids concentration is 12-15% w/w and the beta acids concentration 4-6% w/w.

Zeus: Zeus is also called Columbus or Tomahawk, often referred as CTZ because these

cultivars are so similar that they are categorized as one variety. It is a high alpha-hops with an alpha-acids level of 13-18% w/w and beta-acids level of 4.5-5.5% w/w.

1.8 Previous studies

Previous studies can help to understand how quality analysis of hop cones, as was done in this study in Arkansas, can possibly be done. A study by Forteschi et al. (2019) assessed the quality of Cascade hop grown in Sardinia, Italy. They found that although hops aromatic character is cultivar dependent, differences are present within the same cultivar due to cultivation factors. In this study, the Cascade plants were purchased from the same nursery and cultivated in three regions on similar trellis systems and plant spacing. Temperature and rainfall was monitored for all the regions. The analysis of alpha-and beta-acids and essential oils was performed according to EBC methods. Statistically, no correlation was observed between the data of the different crop years. An attribute that was analyzed was the cohumulone content in relative amount expressed as cohumulone/total alpha-acids ratio. Usually, the lower this relative ratio is the better, because cohumulone is considered responsible for an unpleasant bitterness in beer (Roberts & Wilson, 2006). The main conclusion of this study was that the obtained information was useful to check the possibility to grow hops in Sardinia but more tests will need to be done on the long term to understand the interaction between environment and the crops. Infrastructures that support drying of hop cones after harvesting and pelletizing of these cones will need to be acquired for this future research (Forteschi et al. , 2019).

Regarding quality analysis, bitter taste is an important quality for hops. To successfully determine the bitterness intensity of hop extracts, descriptive sensory panels are used to recognize and distinguish qualities of oral sensations. First panelists need to be trained to get familiar with established aromas or tastes that are specific for hops. An example from a training can be found in the study of Haseleu et al. (2009) which used a solution of MgSO4(166 mmol/L)

to represent a short-lasting metallic bitter taste and a solution of salicin (1.4 mmol/l) representing a long-lasting bitter taste at the back of the throat. Before analyzing, the isolated fractions were suspended in water, and the volatiles were removed in high vacuum. The samples needed to be free of the buffer compound and solvents. Formic acid was used to adjust the pH because it does not influence the sensory profile of the test solution. After HPLC, the isolated fractions were dissolved so that the concentrations would be adjusted to their amount in the hop extract, first in 5% aqueous ethanol solution (10 ml, pH 4.4) and then sequentially diluted 1:2 with bottled water. Each dilution of these fractions was presented to the panel so the bitterness could be evaluated.

1.9 Analysis techniques

The moisture content and levels of alpha-acids, beta-acids, and essential oils in the hops are typically identified on the packages of commercially sold hops. There are several methods and types of equipment that can be used to identify and quantitate key hops components.

1.9.1 Moisture content measurement

As discussed in Chapter 1.4, moisture content measurement can be done in different ways. The most common method is weight loss on drying. For this an oven, hot plate or dehydrator can be used. In this technique, the sample weight is recorded at the start and after drying to determine the moisture content. For hops this can be done by using the formula:

𝑚𝑜𝑖𝑠𝑡𝑢𝑟𝑒 𝑖𝑛 ℎ𝑜𝑝𝑠 (%) = 𝑙𝑜𝑠𝑠 𝑖𝑛 𝑤𝑒𝑖𝑔ℎ𝑡 ∗ 100 𝑤𝑒𝑖𝑔ℎ𝑡 𝑜𝑓 𝑢𝑛𝑑𝑟𝑖𝑒𝑑 𝑠𝑎𝑚𝑝𝑙𝑒 1.9.2 HPLC

The HPLC is used to separate, identify, and quantify certain compounds in a mixture. HPLC makes use of a column and mobile phase to analyze samples. The column is packed with an adsorbent or stationary phase. A pump forces a solvent or mobile phase through the column. This mobile phase can carry the sample for analysis. The separation principle (Figure 13) of HPLC is based on the interactions between the molecules of compounds in a sample. Depending on the chemical structure of the analyte, the molecules are retarded while passing the stationary phase. Molecules that will have a strong interaction with the adsorbent in the column will be bound longer. Molecules that have no affinity with the stationary phase will go faster through the column under the pressure of the mobile phase to achieve separation. A detection unit (for example a UV-VIS detector) can detect the compounds leaving the column. The generated signals are converted via computer software and processed as a chromatogram. With the pump transferring the mobile phase at pressures up to 400 atm, the technique is much faster in comparison to regular column chromatography. To keep the noise of the detector signal as low as possible, a constant and pulseless flow from the pump is crucial. The time required for a compound from the moment of injection until the moment of detection is called the retention time (tR). The delay time (t0) refers

to the time necessary for a non-retarded compound to be transported from injection to the detection site. There are two different modes of HPLC-use. Gradient and isocratic use depends on the composition of mobile phase. If the composition of mobile phase stays constant over the separation process this is called an isocratic elution system. A gradient elution system is when the composition changes during the process. There are also different variants of HPLC. Normal-phase HPLC has a polar stationary phase and a non-polar mobile phase. Reverse-phase has a non-polar stationary phase and a polar mobile phase.

Figure 13: Principle of High Performance Liquid Chromatography (Knauer, 2019)

1.9.3 Spectrophotometry 1.9.3.1 General principle

When a spectroscope uses ultraviolent (UV)-and visible light this technique is called UV-VIS spectroscopy. A light source emits light through a slit on a prism. The light can disperse different spectral wavelengths. By moving a second slit, one can focus on one fixed wavelength. This results in a monochromator (Figure 14). When this monochrome light ray is sent through a sample, specific absorbance can occur. This means that the intensity of the light will be bigger before going through the sample then on the point of leaving it. Because of this, specific molecules can be detected and the concentrations measured.

Figure 14: Principle ultraviolent (UV)-and visible light (VS) spectroscopy

Most spectroscopy techniques work with the use of the Lambert Beer law A = ε*l*c with A the absorbance, ε the absorption coefficient, l the path length and c the concentration for an absorbing component. For a two-component analysis (for example alpha- and beta-acids) this gives: A = εcomp1 * l* ccomp1 + εcomp2 * l* ccomp2

1.9.3.2 Spectrophotometric procedure for hops analysis

Regarding hops alpha- and beta-acids, wavelengths of importance are 275 nm, 325 nm, and 355 nm. Alderton et al. (1954) found that at 275 nm the absorption of both lupulone and humulone complexes was low (Figure 15). Because of this low absorbance, this wavelength provides a relatively high sensitivity to absorbing impurities. This can show other absorbers present which could give interference with the alpha- and beta-acids readings. Humulones and lupulones have absorption maxima at 325 nm and 355 nm. When looking for alpha- and beta-acids, a spectrum usually starts at 275 nm, because the extraction of these compounds usually happens in toluene which has a strong absorbance at 260 nm. Egts et al. (2011) stated that next to toluene, also methanol, ethanol, hexane, and ether are possible extraction solvents with methanol being a very successful solvent. Nevertheless, toluene is mostly used, because this is the industrial standard and gives the best solvation of the hop compounds.

Figure 15: Absorption spectra of lupulone and humulone complex in acidic (0.002N) and alkaline (0.002N) methanol (Alderton et al., 1954)

Although there are only two components of interest, the humulone/lupulone spectroscopy is more complex than a two-component system. Neither the alpha-acids nor the beta-acids are single compounds, they are each a family of different but related compounds with similar absorption characteristics, for example cohumulone, adhumulone and humulone for alpha-acids. Next to the alpha-and beta-acids there is also a third component that appears over time as the alpha- and beta-acids degrade. This component is a breakdown component of the hops which absorbs maximally at 275 nm but also at 325 and 355 nm. This causes interfering with a standard two-component analysis (Egts et al., 2011). Spectroscopy of alpha- and beta-acids is thus a three-component system focusing on the major component families not on the individual compounds. Alderton et al. (1954) found that the alpha-acids have specific absorptivity of 31.8, 38.1, and 9.0 L/(g.cm) at 355, 325, and 275 nm, respectively.

The beta-acids have absorptivity of 46.0, 33.1, and 3.7 L/(g.cm) at the same wavelengths, whereas the third degradation component has absorptivity of 1.0, 1.5, and 3.1 L/(g.cm) at these wavelengths. This results in the three equations:

Rewriting these equations and partially solving them gives the following solution:

This is with the concentrations given in g/L. These formulas are also used in the ASBC- spectrophotometric procedure Hops-6.

2

Materials and methods

2.1 Establishing the hop yard

The hops were planted at one location, the University of Arkansas System Division of Agriculture (UA System) Fruit Research Station (1749 State Hwy 818, Clarksville, AR 72830, United States) in September 2018. This site is in United States Department of Agriculture hardiness zone 7b and has Linker fine sandy loam soil (fine-loamy, siliceous, semi active, thermic Typic Hapludult). The hops were grown on a trellis system that was 3.66 m high with 76.2 cm plant spacing. Each plant had three training lines going to the trellising wire to support three bines per plant. Prowl® pre-emergent herbicide was used in September 2018 prior to planting, and in late September 14th, 2018 each hop plug plant was planted using a hand trowel and were immediately watered. Plug plants were sourced from Agristarts (Apopka, FL, U.S.A.) and Great Lakes Hops (Zeeland, MI, U.S.A.).

On April 30th, 2019 the first application of fertilizer (approximately 48.68 g of “13-13-13” fertilizer per plant or 8.11 g per plant) was scattered by hand. On May 15th, the second round of fertilizer at the same rate was applied, Prowl® pre-emergent herbicide and a fungicide, Pristine, were also used on this date. On May 31st, a hand-crank system was installed to the first wooden post which fed a metal wire across the top of each 4.6 m beam to bolster and eventually lower the bines to facilitate hops harvest. Also, the third application of granular fertilizer (97.36 g of “13-13-13” per plant or 16.23 g per plant) was spread by hand. Multiple two-prong landscape fabric staples each with three 4.6 m pieces of bailing twine attached were implanted at the base of all remaining hops and tied to the top of the trellis wire. During the following week (starting from June 11th), the three most promising, newly-emerged shoots from each

plant were trained clockwise on the twine while any additional shoots throughout the remainder of the summer season were cut back to the ground.

2.1.1 Cultivar study

For the cultivar study, six cultivars (Cascade, Cashmere, Centennial, Crystal, Nugget, and Zeus) were planted in three blocks with three replications per block with randomized planting order. Appendix 2, Figure B.1 shows a representation of the growing site showing the plant numbers, cultivars, and blocks. There were three plants of each cultivar randomized per block, so nine plants per cultivar total. The cultivar-study was conducted on plants 1-53. All plants in the cultivar study were pruned (removal of above-ground crown material) on April 30th.

2.1.2 Pruning study

For the pruning study, an additional nine plants of Cascade were planted to assess the effects of shoot pruning at three different dates (Figure 16). The pruning study was done on plants 55-63 at three different pruning dates including April 15th (Early) for plants 55-57, April 30th (Mid) for plants 58-60, and May 15th (Late) for plants 60-63. There were three replications (plants)