GRASS: A FANTASTIC SOURCE OF

FEED AND FOOD?

Brecht Delmoitié

Student number: 01413314Promotor(s): Prof. dr. ir. Korneel Rabaey Tutor(s): Ir. Myrsini Sakarika

Master’s Dissertation submitted to Ghent University in partial fulfilment of the requirements for the degree of Master of Science in Industrial Science: Biochemistry

GRASS: A FANTASTIC SOURCE OF

FEED AND FOOD?

Brecht Delmoitié

Student number: 01413314Promotor(s): Prof. dr. ir. Korneel Rabaey Tutor(s): Ir. Myrsini Sakarika

Master’s Dissertation submitted to Ghent University in partial fulfilment of the requirements for the degree of Master of Science in Industrial Science: Biochemistry

Deze pagina is niet beschikbaar omdat ze persoonsgegevens bevat.

Universiteitsbibliotheek Gent, 2021.

This page is not available because it contains personal information.

Ghent University, Library, 2021.

ACKNOWLEDGEMENTS

This is it then the end of my master thesis, a turbulent end a lot of people will remember. If I look past this, I’m glad and proud about this thesis year. It was not always stress-free or easy, but I learned a lot about my thesis subject but also about myself and my future. The end result would not be possible without the help of some people.

First and foremost, I would like to express my eternal gratitude towards Myrsini, my tutor. You live for your students supporting them where needed perhaps sometimes a bit too much for your own good and night rest. Even in times such as these you were always there for me, discussing results, correcting my mistakes, etc. I would never have learned as much if it wasn’t for you! I would like to thank you to make time in your busy schedule for me to support me where needed, this would not been possible without you!

Second, a special thanks to professor Korneel Rabaey who gave me this opportunity. While you have an immense busy schedule you always took your time to discuss results and give some interesting ideas as well. Therefore, I would like to thank you.

Furthermore, I would like to thank my fellow master students especially Elise and Melanie. The coffee breaks, the lab work, the lunch breaks were fun and much needed to take some mental break from all the work. I’m so glad to spend so much time with you guys!

At last, a special thanks to my parents while the start of my student career was a bit turbulent you always guided me, supported me and believed in me. Without you this would not have been possible. For all my friends (especially Pieter) and family, thank you for the much needed relaxation time.

Thank you all!!! Brecht Delmoitié

ABSTRACT

One of the most challenging problems in the next decades is to provide food for the growing world population. Estimations show that the population will grow to 9.8 billion people by 2050. Together with the westernization of diets, there is an increasing demand in protein. The production of protein is an inefficient way of producing proteins with regard to CO2 emissions,

nitrogen pollution, freshwater and land use. Current agricultural practices cannot sustain this demand in an environmental manner. To this end, Single Cell Protein (SCP) has been proposed to mitigate this problem.

SCP are proteins derived from microorganisms such as bacteria and yeasts. These microorganisms can convert nitrogen to protein with an efficiency of 80-100%, while animal or plant-based proteins have a nitrogen to protein conversion rate of 4-14%. Another advantage is the quick reproduction of the organisms and the potential to use agricultural or industrial waste streams.

One of these streams can be grass, which is abundantly present in Europe and has low nutrient requirements. Given this availability, a novel protein production approach has been proposed in the frame of a green biorefinery concept. The grass can be divided in a fibre and juice fraction, the fibre can be used for anaerobic digestion. The juice will be used as a fermentation media for SCP production. This fermentation medium contains vital nutrients that need preservation for a SCP production process. For the preservation of the grass juice, lactic acid fermentation was performed by Bacillus coagulans, a thermophilic probiotic spore forming bacterium. The produced lactic acid will be used as a carbon source for a sequential SCP production performed by Cupriavidus necator.

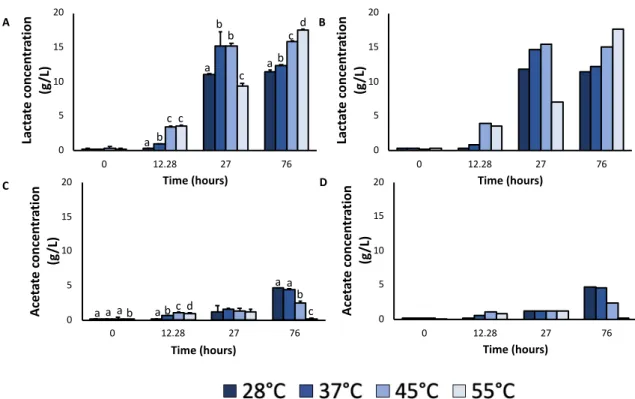

In a first part, lactic acid fermentation was performed on different grass substrates namely fibre, fresh grass, ground grass and grass juice in (non-)aseptic conditions. Sterilisation significantly improved the lactic acid fermentation of the ground and fresh grass with 27.13-50.74% compared to the non-aseptic lactic acid fermentation. The sterilisation of the fibre fraction did not improve the lactic acid fermentation due the preceding fractionation step as a considerable amount of nutrients and carbohydrates were removed. The non-aseptic lactic acid fermentation of the grass juice yielded similar or even higher lactic acid production (44.88%) compared to the aseptic conditions. The non-aseptic lactic acid fermentation of grass juice was considered the most suitable fermentation substrate due to the higher final lactic acid concentration. In the second part, different incubation temperatures were evaluated concerning lactic acid production (28-55°C). The organic acid distribution showed a correlation with the incubation temperature. Specifically, the lactic acid concentration showed a directly proportional relationship while the concentration of acetic acid showed an inversely proportional

similar lactic acid yields compared to the aseptic fermentation indicating towards the presence of a dominant thermophilic homofermentative bacteria in the grass microbiota.

In the following SCP production, lactic acid was used as a carbon source for Cupriavidus necator. To evaluate this carbon source growth parameter estimations were performed on lactic acid concentrations ranging from 8.33 till 166.5 mM. A µmax of 0.64 ± 0.01 h-1 and a

half-saturation constant of 11.25 ± 1.28 mM was obtained. Evaluation of other organic acids µmax

obtained from literature showed the preferential carbon source was lactic acid compared to other organic acids such as butyric acid, formic acid, acetic acid.

SAMENVATTING

Eén van de meest uitdagende problemen in het volgende decennia is het voorzien van voedsel voor de globale groeiende populatie. Schattingen tonen aan dat er in 2050 9.8 miljard mensen op deze planeet zullen leven. Dit samen met de verwestering van bepaalde culturen zorgt voor een sterke toename in de vraag naar dierlijke proteïnen. Huidige agrarische methoden kunnen deze vraag niet beantwoorden op een duurzame manier wat resulteert in CO2 uitstoot,

N-vervuiling, etc. Hiertoe werden microbiële proteïnen (MP) voorgesteld om deze vraag te beantwoorden.

MP zijn eiwitten afkomstig uit organismen zoals bacteriën, gisten. Deze micro-organismen kunnen stikstof omzetten naar eiwitten met een efficiëntie van 80-100% in tegenstelling tot dierlijke of plantaardige proteïnen die een conversie hebben van 4-14%. Naast dit voordeel, reproduceren deze organismen op een snellere manier dan de hogere biota en kunnen ze gebruik maken van goedkope agrarische of industriële afvalstromen.

Gras kan zo een stroom zijn, dit gewas is overvloedig aanwezig in Europa en een ander voordeel is de lage meststof vereisten. Hiertoe werd een nieuwe proteïne productiemethode voorgesteld gebaseerd op een green biorefinery concept. Het gras zal gefractioneerd worden in twee fracties namelijk de vezel en sap fractie. Deze laatste bevat de vitale nutriënten die nodig zijn voor een MP-productie. Echter, moet deze nutriënten bewaard worden door een melkzuur fermentatie. Deze fermentatie zal worden uitgevoerd door Bacillus coagulans een thermofiele probiotische spoor vormende bacterie. Het geproduceerde melkzuur zal gebruikt worden als een koolstofbron voor de opvolgende MP-productie van Cupriavidus necator.

In het eerste gedeelte werd een melkzuur fermentatie uitgevoerd op verschillende gras substraten namelijk de vezel en sap fractie maar ook vers en gemalen gras in steriele en niet-steriele condities. Sterilisatie van vers en gemalen gras significant verbeterde de melkzuur opbrengst met 27,13-50,74% vergeleken met de niet-steriele fermentatie. Het autoclaveren van de vezelfractie leidde niet tot verbetering van de melkzuur opbrengst dit is te wijten aan de voorgaande fractionerende stap. Deze stap zal een groot deel van de nutriënten en koolhydraten verwijderen waardoor er een gelimiteerde hoeveelheid nutriënten aanwezig is voor de melkzuur fermentatie. De niet-steriele fermentatie van het gras sap produceerde evenveel of zelfs 44.88% meer melkzuur vergeleken met de steriele fermentatie. De niet-steriele fermentatie van het gras sap werd beschouwd als het ideale fermentatie medium met betrekking tot de melkzuur opbrengst.

In een tweede stap werden verschillende incubatie temperaturen geëvalueerd (28-55°C) met betrekking tot melkzuur opbrengst. De organische zuur distributie vertoonde een correlatie met een toenemende incubatie temperatuur. De melkzuur concentratie was recht evenredig terwijl het azijnzuur omgekeerd evenredig was met de incubatie temperature. De niet-steriele

fermentatie op 55°C vertoonde gelijkaardige melkzuur opbrengsten vergelijken met de steriele fermentatie van de homofermentatieve Bacillus coagulans. Dit kan wijzen om de dominante aanwezigheid van een thermofiele homofermentative bacterie in het gras microbiota.

In de opeenvolgende MP productie zal melkzuur gebruikt worden als een koolstofbron voor Cupriavidus necator. Om deze koolstofbron te evalueren werden er kritische groeiparameters berekend op verschillende melkzuur concentraties (8.33-166.5 mM). Een µmax van 0,64 ± 0,01

h-1 en een half saturatie constatne van 11,25 ± 1,28 mM werd verkregen. Evaluatie van andere

organische zuren µmax toonde aan dat melkzuur een preferentieel koolstof bron was vergeleken

TABLE OF CONTENTS

Introduction ... 1

I Literature ... 2

1. A biorefinery on grass ... 2

1.1 Benefits of grass as raw material ... 3

1.2 Preservation of grass juice characteristics through lactic acid fermentation ... 4

2. Single Cell Protein ... 5

2.1 History ... 5

2.2 Nutritional value ... 5

2.2.1 Protein and amino acids ... 5

2.2.2 Additional beneficial characteristics of microorganisms ... 7

2.2.2.1 Probiotics ... 7

2.2.2.2 Prebiotics ... 10

2.3 Sustainability of Single Cell Protein production ... 11

3. Restrictions in the use of microorganisms as feed or food ingredient ... 14

II Objectives ... 16

III Materials and methods ... 18

1. Microbial cultures ... 18

2. Pre-culture preparation ... 18

3. Maximizing lactic acid production from the grass feedstock through temperature and pre-treatment evaluation ... 19

3.1 Batch fermentation ... 19

3.2 (Non-)aseptic lactic acid fermentation and temperature evaluation ... 19

3.3 The effect of pre-treatment of grass on the (non-)aseptic lactic acid fermentation ... 20

4. Growth curves ... 21

5. Single cell protein production on lactic acid ... 22

5.1 Batch experiment of single cell protein production based on concentrated extract of ... 22

5.2 Batch experiment of sequential single cell protein production ... 22

6. Analytical methods ... 23

6.1 Organic acid and anion/cation analysis ... 23

6.2 Total solids/volatile solids and total suspended solids/volatile suspended solids ... 23

6.3 Total protein ... 24

6.4 Total carbohydrates ... 24

6.5 pH and conductivity ... 25

7. Data analysis ... 25

7.1 Growth rate calculations ... 25

7.2 Lactic acid yield ... 25

7.3 Statistical analysis ... 26

2. Lactic acid fermentation ... 28

2.1 Non-aseptic fermentation ... 28

2.1.1 Organic acid production ... 28

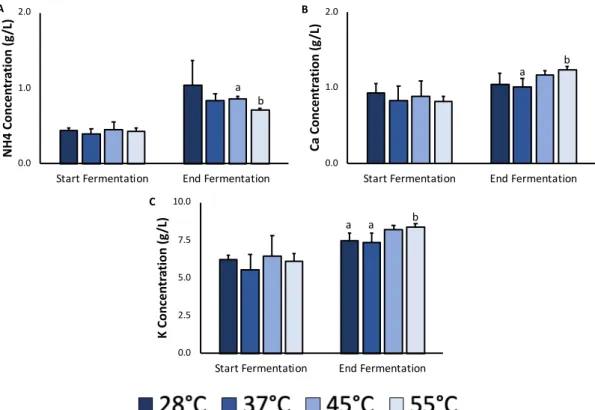

2.1.2 Cation composition during fermentation ... 30

2.1.3 TS/VS and TSS/VSS ... 31

2.2 Aseptic fermentation ... 32

2.2.1 Organic acid production ... 32

2.2.2 Anions/cations during fermentation ... 33

2.2.3 TS/VS and TSS/VSS concentrations ... 34

2.2.4 Lactic acid conversion yield ... 35

3. Effect of feedstock composition on the lactic acid production ... 36

3.1 Effect of feedstock composition on the lactic acid production ... 36

3.2 Effect of sterilization of different feedstocks concerning lactic acid production ... 37

3.3 Effect of incubation temperature on the lactic acid production ... 38

3.4 Effect of the incubation temperature on the non-aseptic condition concerning acetic acid production ... 39

4. Evaluation of the antimicrobial effect of sorbic acid ... 39

4.1 The effect of sorbic acid on the growth of Bacillus coagulans ... 39

4.2 The effect of sorbic acid on the growth of Cupriavidus necator ... 40

5. Parameter estimation of the growth of Cupriavidus necator on lactic acid ... 41

6. Evaluation of the different SCP production approaches ... 42

6.1 Sequential SCP production approach ... 43

6.2 SCP production approach on extracted lactic acid ... 44

V Discussion ... 46

1. Effect of autoclaving on the feedstock composition ... 46

1.1 Effect of autoclaving on the grass juice characterisation ... 46

1.2 Hydrolysis of feedstock through sterilisation ... 47

2. Evaluating the grass substrates as a feedstock for lactic acid production ... 48

3. Steering the microbiota towards a homofermentative production state through temperature increase 49 4. Assessment of the biomass production during LA fermentation ... 51

5. Sorbic acid as a growth inhibiting compound ... 52

5.1 Antimicrobial effect of sorbic acid on Bacillus coagulans ... 52

5.2 Antimicrobial effect of sorbic acid on Cupriavidus necator ... 53

6. Screening of lactic acid concentrations as carbon source for Cupriavidus necator ... 54

7. Evaluation of the SCP production approaches ... 55

7.1 Sequential SCP production approach ... 55

7.2 SCP production approach on electrochemical extracted lactic acid ... 56

8. Assessment of the green biorefinery as a novel protein production route ... 57

VI ConclusionS ... 60

VIII References ... 63

IX Appendix ... 73

1. The nutritive value of different dietary protein sources ... 73

2. The environmental impact of different protein sources ... 73

LIST OF ABBREVIATIONS

AA Acetic acid

AAA Aromatic amino acids

AMS Ammonium mineral salts

COD Chemical oxygen demand

EC Electrical conductivity

FAO Food and agriculture organisation

IBS Irritable bowel syndrome

LA Lactic acid

LAB Lactic acid bacteria

MDD Major depressive disorder

MP Microbial protein NA Nutrient agar NB Nutrient broth OA Organic acids OD Optical density PHB Polyhydroxybutyrate

PLA Polylactic acid

RDA Recommended dietary allowances

SA Sorbic acid

SAA Sulphur containing amino acids

SCFA Short chain fatty acids

SCP Single cell protein

TS Total solids

TSA Tryptic soy agar

TSS Total suspended solids

UASB Upflow anaerobic sludge blanket

VS Volatile solids

VSS Volatile suspended solids

LIST OF FIGURES

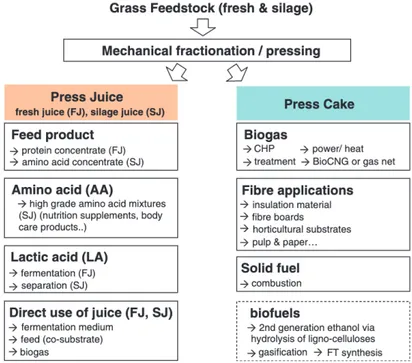

Figure 1: General products from a green biorefinery. The press cake can be used to produce biogas and fuel

a combined heat and power plant or after treatment it can be utilised as a compressed natural gas to fuel vehicles. It can also be used in different fibre applications or as a solid fuel. The pressed cake can be converted through gasification into a Fisher-Tropsch fuel. The press juice can be used as feed product (amino acids, protein) or used as a fermentation medium (Mandl, 2010). ... 3

Figure 2: Essential amino acid content of Chlorella vulgaris, Fusarium venenatum and Cupriavidus necator.

Compared to traditional dietary protein sources like beef and soybeans. All these protein sources are assessed against the FAO standard. SAA or sulphur containing amino acids includes methionine and cysteine. AAA or aromatic amino acids includes tryptophan and phenylalanine. The data is expressed in g amino acid/ 100 g available protein (Ahangi et al., 2008; Mazhangara et al., 2019; Mohamed et al., 2013; Mohsen et al., 2009; Swaminathan et al., 2012; Volovaa et al., 2010). ... 6

Figure 3: The sporulation scheme of spore forming bacteria under abiotic stress like starvation or high

temperatures. When suitable abiotic conditions occur, the bacteria germinate from spores towards a vegetative cell cycle (Cutting, 2011). ... 9

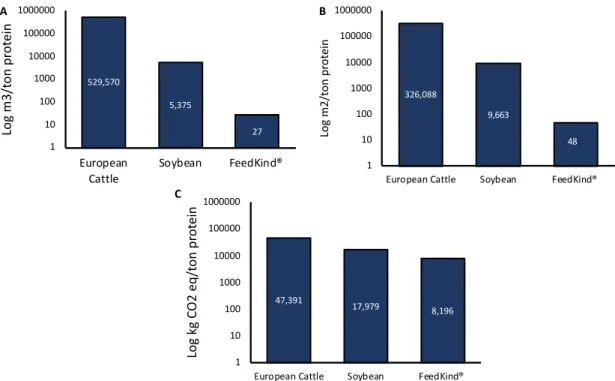

Figure 4: The path towards sustainable protein production (Molitor et al., 2019) ... 12 Figure 5: Environmental effects of different protein sources. Figure A shows the water footprint of one tonne

produced protein. Figure B shows the land footprint of one tonne produced protein. Figure C shows the carbon footprint (in CO2 equivalents) for one tonne of protein. ... 13

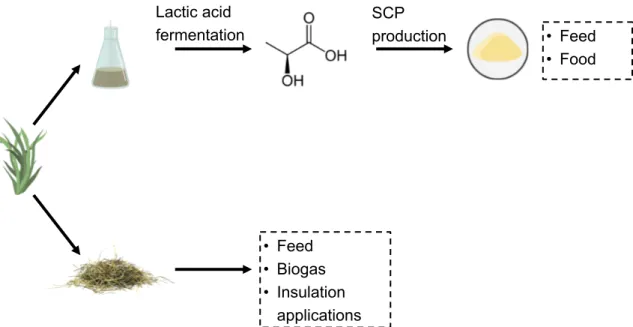

Figure 6: The Power-To-Protein power principle (“About – Power to Protein,” n.d.) ... 14 Figure 7: Proposed protein production approach. The grass will be fractionated towards grass juice and

pressed cake. The pressed cake can serve as a feedstock for biogas production or as feed ingredient. The available carbohydrates in the grass juice will be converted towards lactic acid and biomass through a selective lactic acid fermentation. The produced lactic acid will serve as carbon source for the sequential or decoupled SCP production approach. ... 17

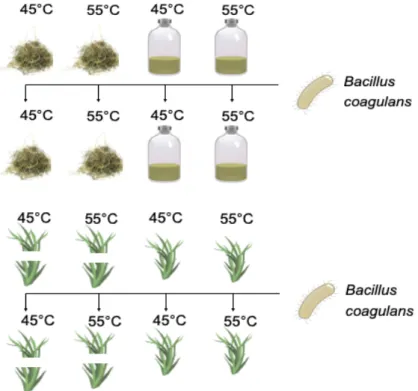

Figure 8: Experimental set-up for (non)-aseptic fermentation. Four serum vials at each temperature were

inoculated with Bacillus coagulans. The control in the non-aseptic conditions will contain natural present microbial cultures in the grass etc. During the lactic acid fermentation, the pH will drop and inhibit any further microbial lactic acid production. This will be resolved through pH adaption two times a day with 5 M NaOH. This experimental set-up is repeated for the aseptic lactic acid fermentation, the only difference will be the aseptic procedures during sampling and pH adaptation. ... 20

Figure 9: Experimental set-up for (non-)aseptic lactic acid fermentation on different grass substrates namely

grass juice, pressed cake (fibres), ground grass and fresh grass. Four serum vials were inoculated with B. coagulans while one serum vial served as a control without any intended inoculation of B. coagulans. For each treatment and each incubation temperature (45°C-55°C) this was repeated. ... 21

Figure 10: The organic acids produced during the non-aseptic fermentation are shown in the graphs above.

A) shows the lactate production during the fermentation of grass juice inoculated with B. coagulans. B) shows the lactate production of the control fermentation C) shows the acetate production during the fermentation of the grass juice inoculated with B. coagulans. D) shows the acetate production of the control fermentation. The error bars of A and C are the standard deviation of the biological replicates. The letters a, b, c and d show a significant difference (p <0.05) between the different temperatures obtained from a Dunnet or Tukey-Kramer post hoc analysis. ... 29

Figure 11: The cation concentrations that were measured during the non-aseptic lactic acid fermentation. A)

shows the NH4+ concentrations that were measured during the fermentation. B) shows the Ca2+ concentrations that were measured during fermentation. C) shows the K+ concentrations that were measured during the fermentation. The error bars are the standard deviation of the biological replicates. The letters a, b, c and d show a significant difference (p <0.05) between the different temperatures obtained from a Dunnet or Tukey-Kramer post hoc analysis. ... 31

Figure 12: The TS/VS and TSS/VSS that were measured during the non-aseptic lactic acid fermentation. A)

shows the TS (w/w%) concentrations that was measured during the end and the start of the fermentation. B) shows the VS (w/w%) concentrations that was measured during fermentation. C) shows the TSS (g/L) that was measured during the fermentation. D) shows the VSS (g/L) that was measured during the fermentation. The error bars are the standard deviation of the biological replicates. The letters a, b, c and d show a significant difference (p <0.05) between the different temperatures obtained from a Dunnet or Tukey-Kramer post hoc analysis. ... 32

Figure 13: The lactic acid production during the aseptic fermentation is shown in the graph above. The error

bars are the standard deviation of the biological replicates. The letters a, b, c and d show a significant difference (p <0.05) between the different temperatures obtained from a Dunnet or Tukey-Kramer post hoc analysis. ... 33

Figure 14: The anion/cation concentrations that were measured during the aseptic lactic acid fermentation.

A) shows the NH4+ concentrations that were measured during the fermentation. B) shows the Mg2+ concentrations that were measured during fermentation. C) shows the Cl- concentrations that were measured during the fermentation. D) shows the PO43- concentrations that were measured during the fermentation E) shows the K+ concentrations that were measured during the fermentation. The error bars are the standard deviation of the biological replicates. The letters a, b, c and d show a significant difference (p <0.05) between the different temperatures obtained from a Dunnet or Tukey-Kramer post hoc analysis. ... 34

Figure 15: The TS/VS and TSS/VSS that were measured during the aseptic lactic acid fermentation. A)

shows the TS (w/w%) concentrations that was measured during the end and the start of the fermentation. B) shows the VS (w/w%) concentrations that was measured during fermentation. C) shows the TSS (g/L) that was measured during the fermentation. D) shows the VSS (g/L) that was measured during the fermentation. The error bars are the standard deviation of the biological replicates. The letters a, b, c and d show a significant difference (p <0.05) between the different temperatures obtained from a Dunnet or Tukey-Kramer post hoc analysis. ... 35

Figure 16: Lactic acid yield based upon carbohydrate consumption. For each temperature the consumed

carbohydrates in equivalents glucose was calculated. Through the lactate fermentation one mole glucose should theoretically yield two mole lactic acid. The yield was calculated based on the produced lactic acid divided by the theoretically yield of LA based on the consumed carbohydrates. The error bars are the standard deviation of the biological replicates. ... 36

Figure 17: The lactic acid concentration at the end of the LA fermentation for each feedstock. The error

bars are the standard deviation of the biological replicates. The letters a, b, c and d show a significant difference (p <0.05) between the different temperatures. ... 37

Figure 18: The lactic acid concentration at the end of the fermentation for the aseptic or non-aseptic

conditions. The error bars are the standard deviation of the biological replicates. ** shows a p-value <0.0001. * shows a p-value <0.001. ... 38

Figure 19: Lactic acid concentration at the end of the fermentation A) shows the non-aseptic fermentation

temperatures (45°C, 55°C). The error bars are the standard deviation of the biological replicates. * shows a p = 0.02. ... 38

Figure 20: Acetic acid production during the non-aseptic fermentation. Two different incubation

temperatures were tested: 45°C and 55°C. The error bars are the standard deviation of the biological replicates. ** shows a p < 0.02. * shows a p=0.034. ... 39

Figure 21: The growth curves of Bacillus coagulans DSM 2314 on antimicrobial food grade sorbic acid

concentrations ranging from 0%-1.2%. A) shows the growth curve with a pH of 4. B) shows the growth curve with pH 5. C) shows the growth with pH 6. ... 40

Figure 22: The growth curves of Cupriavidus necator LMG 1199 on antimicrobial food grade named sorbic

acid was evaluated. Sorbic acid concentrations between 0% and 1.2% were evaluated at a pH of 7. ... 41

Figure 23: A) shows the specific growth rates of Cupriavidus necator LMG 1199 on lactic acid

concentrations ranging from 0 mM till 166.5 mM. The growth parameters are estimated using a Monod Model. B) Shows the lag phases of the lactic acid concentrations (0-166.5 mM) obtained from the growth curves. ... 42

Figure 24: The pH development from the sequential SCP production approach. The grass juice contained B.

coagulans and C. necator and the pH was regulated to an optimal of 7. This figure shows the pH progression of grass juice diluted with H20. The error bars are the standard deviation of the biological replicates. ... 43

Figure 25: The lactic acid and acetic acid production/consumption during the sequential SCP production

approach. A) shows the grass juice diluted with H2O and where only B. coagulans is present. B) shows the grass juice diluted with H2O inoculated with B. coagulans and C. necator. The error bars are the standard deviation of the biological replicates. The letters a, b, c and d show a significant difference (p <0.05) between the different temperatures. ... 44

Figure 26: The pH progression from the SCP production approach on simulated electrochemical lactic acid.

The synthetic media contained trace elements and vitamins as well as lactic acid as carbon source. The media was inoculated with C. necator and daily pH measurements were performed and adapted to a pH of 7. The error bars are the standard deviation of the biological replicates. ... 44

Figure 27: The lactic acid consumption of C. necator on synthetic lactic acid supplemented with trace

elements and vitamins. The error bars are the standard deviation of the biological replicates. The letters a, b, c and d show a significant difference (p <0.05) between the different temperatures. ... 45

Figure 28: The organic acid distribution (lactic acid and acetic acid) of the natural fermentation or

non-aseptic fermentation and of the non-non-aseptic fermentation inoculated with B. coagulans. The total organic acid production is also presented for the non-aseptic fermentation as well as the total lactic acid production in aseptic conditions. ... 49

Figure 29: The organic acid distribution (lactic acid and acetic acid) of the natural fermentation or

non-aseptic fermentation and of the non-non-aseptic fermentation inoculated with B. coagulans. The total organic acid production is also presented for the non-aseptic fermentation as well as the total lactic acid production in aseptic conditions. ... 50

Figure 30: Proposed protein production route based on a green biorefinery approach. The green biomass will

be used for fractionation resulting in a press cake suitable for feed applications and a green/grass juice which can be used for lactic acid fermentation performed by B. coagulans. The protein and the biomass produced can be harvested and as well used for a feed application. The remaining lactic acid can be electrochemical extracted and used as a carbon source for food SCP. ... 59

LIST OF TABLES

Table 1: Food components in general dietary proteins like soybeans or beef but also single cell protein

originating from algae, fungi or bacteria compared against recommended dietary allowances (RDA). The values are given in % of the total product * calculated for 70 kg individual **dependent on LDL or HDL *** dependent on substrate and fermentation conditions. (Anupama et al., 2000; Caballero et al., 2016; Mohamed et al., 2013; National Academies Press, 2005; Tessari et al., 2016; Wiebe, 2002) ... 6

Table 2: Overview of advantage and disadvantages of different Single Cell Protein sources (Anupama et al.,

2000; Matassa, 2016) ... 15

Table 3: The origin of the different grass batches, when it was mowed, collected and fractionated). Also,

some extra details are included about the location, visual composition, etc. ... 19

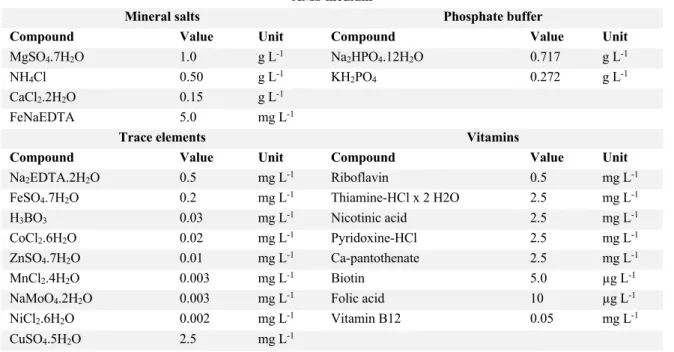

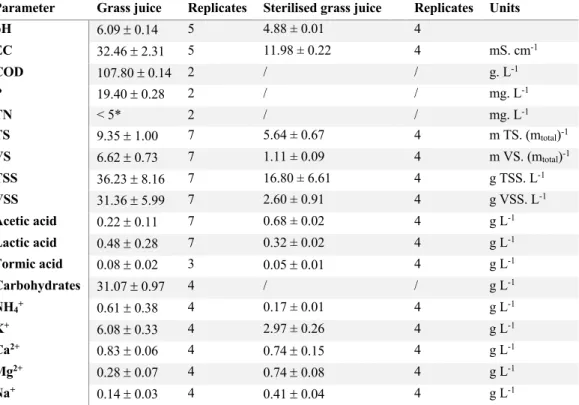

Table 4: The composition of the AMS medium used in following experiments ... 22 Table 5: Grass juice characterisation of the grass juice. The grass batch originated from

Bourgoyen-Ossenmeersen at Ghent. *out of range of Nanocolor kit ... 27

Table 6: The TS and VS of three different grass feedstocks namely fibre, fresh and ground grass. All

feedstocks were derived from the same grass batch ... 27

Table 7: Maximum specific growth rate of C. necator on different carbon sources ... 54 Table 8: The effect of the three different scenarios on the soybean import and there effect on the CO2 emissions, the net CO2 emissions if the grasslands are used as carbon sinks and at last the H2O reduction. Parameters are calculated based on the worst-case scenario (low interval limit) as well as the best-case scenario (upper interval limit). ... 58

Table 9: The effect of a feed-food green biorefinery production approach on parameters such as CO2 equivalents, net CO2 compared to the potential of the grasslands that can function as a carbon sink. At last the H2O reduction is given. ... 59

Table 10: The amino acids composition of different dietary protein sources ... 73 Table 11: Water, Land footprint and carbon footprint for traditional protein sources (beef and soybeans) and

a SCP from FeedKind® The values of the parameters are expressed with the units found in the literatures. 74

Table 12: Water, Land footprint and carbon footprint for traditional protein sources (beef and soybeans) and

a SCP from FeedKind® The data is shown in ton protein of each product. ... 74

Table 13: Three different scenarios were used for calculations. Scenario 1 is based on the recovery of proteins

present in the grass juice. Scenario 2 is based on only SCP of C. necator. At last scenario 3 is a combination of both scenarios. Parameters are calculated based on the worst-case scenario (low interval limit) as well as the best-case scenario (upper interval limit). ... 75

PREAMBLE

Due the current pandemic of COVID-19, me as well as other could not complete our dissertation as desired. A few experiments were cancelled through the lockdown measurements taken by the government. During the end phase of my thesis I was planning to perform carbohydrate analysis of the non-aseptic lactic acid fermentations to assess the substrate utilisation compared to the aseptic fermentation. Beside this, a SCP production approach would be validated on a reactor scale of 1L. During this experiment data such as protein content, biomass, lactic acid consumption would have been measured. While sufficient data to finish my dissertation was obtained, a small case study about the potential of the green biorefinery in Europe was performed.

This pandemic also affected many students their well-being causing an increase in anxiety etc. Currently I’m only feeling the impact of the isolation on my social life, missing my friend, etc. Beside this, I’m also a bit disappointed that I not achieved my end goal of my dissertation to produce SCP. Based on this, I hope my findings can be a starting point for following thesis students. Overall, I can cope with this as this where unusual circumstances for everyone professors, tutors, students. At the end of the day all that matters is that we all survive this crisis together.

This preamble was in consultation between the student and the supervisor and by both approved.

INTRODUCTION

One of the biggest problems in the next decade is the rapid growth of the world’s population. Estimations show that the population will grow to 9.8 billion people by 2050 (United Nations, 2017). With this increase in population there is also a need for an increase in food production. However, the current agriculture system cannot sustain the upcoming food demand. In regions with the highest population growth rate, like Africa, they heavily rely on the slash and burn method, which emits high amounts of greenhouse gases mainly carbon dioxide (Tinker et al., 1996). Because of this approach, climate change will accelerate even further and causes more drastic weather conditions, which in turn affects the overall agricultural yield (Powell & Reinhard, 2015).

Another problem is the westernization of the food habits. This is caused by the increase off the overall income of the population. This higher income triggers a shift towards an animal protein-based diet (Mathijs, 2015). This diet is also an inefficient and polluting way of producing proteins. For example, cattle convert 4.0 % of the protein input to animal product and produce 7.61 kg-49.89 kg CO2eq per 100 grams of protein (Ritchie & Roser, 2017, 2020). Solutions for

a higher protein content and a more sustainable production is necessary for feed or food. One solution can be the production of Single Cell Protein (SCP). These proteins are derived from cultivated microorganisms like algae, fungi or bacteria. These can be used as feed ingredient or a more promising solution to be incorporated into the human diet. SCP production has a number of benefits. Specifically, the quick reproduction of the organisms and the potential for use of cheap industrial or agriculture waste streams, are assets for the production of a cheap protein replacement (Anupama & Ravindra, 2000).

An example of this inexpensive feedstock is grass, which is an abundantly available crop and already used as a winter feed for cattle. However, grass can only be cultivated from spring till late summer. After harvesting the nutritious value of grass needs to be preserved, this is achieved through ensiling (Harrison et al., 1994). But this is not the only function of grass. It can also be used in green biorefinery where it is fractionated into a solid part (press cake) and a liquid part (green juice). The pressed cake has already an economic value, it can be used as feed pellets, isolation material or in the production of cardboard (“Company – Creapaper,” n.d.). The main challenge in the green biorefinery is to utilize the green juice. After harvesting the product already starts to ferment. This uncontrolled fermentation causes a deterioration in the quality of the juice (Lübeck & Lübeck, 2019).

A quick preservation method is needed to preserve the characteristics of the juice. Lactic acid fermentation is viewed as a promising method to conserve the characteristics of this nutrient-rich stream (Thomsen & Kiel, 2008). This causes the pH to drop drastically thereby it inhibits the growth of spoilage microorganisms and pathogens (Harrison et al., 1994; Lübeck et al., 2019).

The scope of this research was to (i) preserve the nutrients of grass juice through lactic acid fermentation through selective growth of a thermophilic lactic acid producer (Bacillus coagulans) and (ii) increase the protein content of the grass juice through a second fermentation by Cupriavidus necator. By utilizing a probiotic strain (B. coagulans) and prebiotic producer (C. necator) the overall nutritional value of grass (protein, probiotic and prebiotic) will be increased.

I LITERATURE

1. A biorefinery on grass

Most of modern economy revolves around one industrial raw material: petroleum. By refining this petroleum, it can fuel our cars, planes and our electricity needs. But is also creates lots of chemical products: plastics, fertilisers, detergents and even medicines (“UKOG - Why oil is important,” n.d.). However, through these manufacturing processes and combustion of the fuel, CO2 is emitted to the atmosphere. This greenhouse gas (GHG) traps heat radiating from earth

towards space, causing the global temperature to rise with drastic consequences like extreme weather conditions. A more sustainable way is needed to produce fuels and bulk chemicals (Mandl, 2010).

Green biorefinery can be a solution for two global problems: a fossil fuel-based economy and the future food provision. Green biorefinery is a multi-product producing system, which is based on green biomass like grass, clover, alfalfa (Figure 1) (Kamm & Kamm, 2004). The biorefinery consists out of two refinery steps, the primary is the fractionation of the grass producing a pressed cake and a green juice. The fibre rich pressed cake contains cellulose and starch. The nutrient rich green juice contains all the soluble organics like proteins, amino acids, organic acids, enzymes, minerals, etc (Mandl, 2010).

The secondary refinery produces different high value products or energy. The pressed cake can be used to produce biogas, 2nd generation biofuel or as solid fuel. However, the fibres can be

converted to insulation material or to paper and cardboard. Because of the high cellulose and starch content it can also be applied as feed substituent. The higher concentrations of proteins present in the green juice can be coagulated (brown juice) and be utilized as protein concentrate

in feed. Since the juice contains a high concentration of unexploited nutrients it is an ideal fermentation broth, which can be used to produce lactic acid as a platform chemical (Mandl, 2010).

Figure 1: General products from a green biorefinery. The press cake can be used to produce biogas and fuel a combined heat and power plant or after treatment it can be utilised as a compressed natural gas to fuel vehicles. It can also be used in different fibre applications or as a solid fuel. The pressed cake can be converted through gasification into a Fisher-Tropsch fuel. The press juice can be used as feed product (amino acids, protein) or used as a fermentation medium (Mandl, 2010).

1.1 Benefits of grass as raw material

So, why is grass such an interesting product? First of all, due its abundance in many regions. Due the reduction in dairy farms in Europe there are an estimated 15-20 % unexploited grasslands. On average unrefined grass contains 6-15 % proteins through use of this untapped protein source the import of soybean meal (10 million ton) can be reduced by 3 million ton and as a consequence, reduce the overall CO2 emissions (Mandl, 2010).

The large diversity of grass species makes the application of green biorefinery attractive, as the species can be selected for different marginal lands (POWERGEN, n.d.). By utilising marginal lands to produce biofuel, protein, etc. it can be used as a supplementation or even replacement for the current food or fuel production. In contrary making use of agricultural land to cultivate edible crops to produce biofuel production has caused a lot of controversy. However, with further technology developments second generation biofuels can be produced out of the non-edible plant parts (Bosworth, 2015). Grass is also considered a high yield crops with low nutrient requirements. This contributes to the economic feasibility of green biorefinery, as none or little extra resources like fertilisers, herbicides, etc. are needed (Bosworth, 2015).

The overall key advantage of green biorefinery is the CO2 emission reduction compared to

traditional petroleum refinery. Biorefinery in general can provide for the global energy requirements by producing biogas, solid fuel (pellet) or biofuels. However, it can also provide chemical building blocks, like lactic acid, to produce bulk chemicals (Cherubini, 2010; Dusselier et al., 2013).

1.2 Preservation of grass juice characteristics through lactic acid fermentation

The main problem in green biorefinery is the dependence on the seasonal availability of the grass. After harvesting the grass starts immediately with an uncontrolled fermentation, which is detrimental for the quality and consistency of the end product. This uncontrolled fermentation can be inhibited with a preservation method of the juice, the cake or even the whole crop (Lübeck et al., 2019; Shurkhno et al., 2006).

This preservation can be achieved by a lactic acid fermentation through lactic acid bacteria (Lactobacillus, etc.). They derive their energy needed for cell growth and metabolism from a process called anaerobic respiration or fermentation. This process converts the available sugars to LA. This will cause a drop in pH which will inhibit growth of most spoilage microorganisms. The fermentation process itself can be classified in two different processes homofermentative or heterofermentative. Homofermentative bacteria catabolise sugars in one end product: LA. The heterofermentative bacteria utilise the available sugars and convert through to LA and ethanol or acetic acid (Lübeck et al., 2019; Shurkhno et al., 2006).

Not only the microbial inhibition caused by lactic acid (LA) is an interesting aspect of this compound, it is also being evaluated as a future commodity chemical. It can be used as building block to produce polylactic acid (PLA), which is a biodegradable plastic (Choi et al., 2015). But LA can also be converted towards chemicals as propylene glycol, pyruvic acid, acetaldehyde, and 2,3-pentanedione which all can be used in different applications: flavour, antifreeze, etc (Mäki-Arvela et al., 2014). LA can also be used as a carbon source for other bacteria with higher nutritional value, Corynebacterium glutamicum can utilise LA to produce L-lysine an essential amino acid (Thomsen et al., 2008).

The Lactobacillus genera is already utilised for many centuries, it is commonly used in fermented products like cheese, wine, yoghurt, etc. One of the benefits of this bacteria genera is the probiotic characteristics. However, most foods are being sterilised or pasteurised while Lactobacillus is not heat resistant and the food product will simultaneously lose the probiotics characteristics of the strain. This is one of the reasons B. coagulans is being reviewed as a possible replacement, as it contains both desired qualities: probiotic and heat resistant through spore forming (Konuray & Erginkaya, 2018).

2. Single Cell Protein

2.1 History

In essence, SCP are proteins derived from microorganisms like algae, fungi and bacteria. At first sight it seems to be an unconventional protein source. However, bacteria and fungi are already used for many centuries in different food productions such as cheese, bread, beer. During World War I overall food production decreased, and food was rationed. To prevent this Candida utilis was mass produced as a protein supplement. After the World Wars this revisionary idea of protein production slowly died mainly due the cheap production of soybean and fishmeal proteins (Jiru & Melku, 2018).

Due the conjecture population growth and unsustainable current agricultural system, this idea of protein production is reconsidered. A few types of SCP are already commercially available. Marlow foods Ltd is a company, established in the 80s, that markets meat replacements or QuornTM. These replacements are based on mycoproteins produced by Fusarium venenatum. In

recent years the company is gaining more popularity, in 2017 it reached a growth of 16 % due the population growth and the change in human diets (Finnigan et al., 2019; Quorn, 2018). In recent years more and more companies focus on SCP production. Calysta® produces a protein

supplement for aquaculture, livestock and even pet feed called FeedKind®. They produce the

proteins with natural gas as a raw material. Through the use of natural gas, Calysta® decreased

the amount of land and water used, two limitary factors of the current food production (Calysta, n.d.).

2.2 Nutritional value

2.2.1 Protein and amino acids

An important factor of food or feed is the nutritional composition of the product. The composition of food products mostly consists of carbohydrates, lipids, proteins and vitamins (Cheung, 2015). Hence the importance to determine the content of available proteins in the product. An average individual requires a daily intake of around 50 g of protein to sustain him/herself (National Academies Press, 2005). An overall comparison can be made between different dietary protein sources like soybeans and beef and SCP deriving from commonly used microorganisms for SCP production like Chlorella sp., Fusarium veneatum and Cupriavidus necator, the latter is currently being evaluated as a SCP (Table 1) (Anupama et al., 2000).

Table 1: Food components in general dietary proteins like soybeans or beef but also single cell protein originating from algae, fungi or bacteria compared against recommended dietary allowances (RDA). The values are given in % of the total product * calculated for 70 kg individual **dependent on LDL or HDL *** dependent on substrate and fermentation conditions. (Anupama et al., 2000; Caballero et al., 2016; Mohamed et al., 2013; National

Academies Press, 2005; Tessari et al., 2016; Wiebe, 2002)

Component RDA* (g/day) Soybean (%) Beef (%)

Chlorella vulgaris (%) *** Fusarium venenatum (%) *** Cupriavidus necator (%) *** Protein 49.7 38.9 18-23 51.45 30-70 74.2 Fat NA** 40 12-15 12.18 3.2-4.2 6.0 Nucleic acids NA 1.1-4.0 0.5 4-6 9.70 15-16

The supply of using dietary proteins is essential to provide the essential amino acids. The essential amino acids are indispensable, for different protein structures in the human body, as they cannot be synthesized by the human body. Therefore, a well-balanced diet can provide these required amounts of amino acids (Appendix 1:Table 1).

The amino acid profile of the SCP (i.e. C. vulgaris, F. venenatum and C. necator) is similar compared to the commonly used dietary protein sources. Beside the comparable amino acid content of SCP, it also meets the FAO/WHO requirements for amino acid content in a humankind diet. This makes SCP an interesting direct source of proteins (Ahangi et al., 2008; Mazhangara et al., 2019; Mohamed et al., 2013; Mohsen et al., 2009; Swaminathan et al., 2012; Volovaa & Barashkovb, 2010).

Figure 2: Essential amino acid content of Chlorella vulgaris, Fusarium venenatum and Cupriavidus necator. Compared to traditional dietary protein sources like beef and soybeans. All these protein sources are assessed against the FAO standard. SAA or sulphur containing amino acids includes methionine and cysteine. AAA or aromatic amino acids includes tryptophan and phenylalanine. The data is expressed in g amino acid/ 100 g available protein (Ahangi et al., 2008; Mazhangara et al., 2019; Mohamed et al., 2013; Mohsen et al., 2009; Swaminathan et al., 2012; Volovaa et al., 2010).

0 1 2 3 4 5 6 7 8 9 10

Isoleucine Leucine Lysine Valine Threonine Histidine SAA AAA

% Am in o Ac id s in A va ila bl e Pr ot ei n

FAO standard Soybean

Beef Chlorella vulgaris

2.2.2 Additional beneficial characteristics of microorganisms

Besides high protein content and suitable amino acid profile, SCP can also contain other beneficial nutritional compounds like antioxidants, vitamins, carbohydrates, polyhydroxybutyrate, lipids, etc. For example, some algae produce microbial oil a suitable replacement for vegetable oils in food supplements. This oil contains a high concentration of fatty acids, a particularly interesting fatty acid is the omega-3-fatty acid. Which can be used in clinical purposes for the concentration and purification of eicosapentaenoic acid and docosahexaenoic acid (Matassa, 2016). Furthermore, some microorganisms can contribute towards beneficial health effects on individuals and livestock. These microorganisms contain probiotic or prebiotic characteristics aiding in the balance of the gut microbiota (Matassa, 2016).

2.2.2.1 Probiotics

While microorganisms have higher protein content and a comparable amino acid composition as common dietary protein sources. Some microorganisms can contribute towards beneficial health effects on individuals and livestock. Since people started to ferment food products, they experienced the health benefits of those products. However, merely in the early 1900s scientists started focussing towards those benefits. Metchnikoff was the first person to associate those health benefits with microbes. He introduced the first definition of probiotic as a beneficial effect on human and animal health contributed by microbes (George Kerry et al., 2018). A recent definition was given by World Health Organisation: “live microorganisms which when administered in adequate amounts confer a health benefit on the host” (FAO/WHO, 2016). The health benefits are associated with probiotics originate from influencing the balance in the gut’s microflora (Stanton et al., 2003). A recent metatranscriptomic analysis researched the different functional roles of a healthy microbiome. They discovered that the overexpressed genes were correlated with carbohydrate metabolism, immunogen responses, energy conversion, etc (Hemarajata & Versalovic, 2013). The microflora not only contribute towards these pathways, but they also can alter the gene expression in the hosts guts mucosa and affecting the overall nutrient adsorption, energy metabolism, etc. (Hemarajata & Versalovic, 2013).

Unbalanced microflora can result in less inhibition of pathogenic species and will overall induces a deteriorating of the hosts health. Individuals with an unbalanced microbiome are more susceptible to diseases like cancer, inflammatory bowel syndrome, obesity etc (Kovatcheva-Datchary et al., 2013). The Flemish Gut Flora Project even linked mental health issues like depression, anxiety towards a deprivation of Coprococcus and Dialister sp. All this research

implies that maintaining a balanced microflora is important for sustaining an individual’s health (Valles-Colomer et al., 2019).

Probiotic as the new antibiotic

Antibiotics are a chemical compound inhibiting the growth or even eradicating of bacteria. It has been a therapeutic drug for many years saving many lives. However, through an overuse of antibiotics in agriculture and medicine, bacteria are developing resistance against antibiotics causing a decline of the usefulness of antibiotic treatments. This resistance also occurs in the intestinal microbiome creating a microflora dominated by different resistant species and so disrupting the balanced ecology (Nami et al., 2015).

Because of the antibiotic supplementation in animal feed and the increasing multi-drug resistant microorganism, the European Union implemented in 2006 a total ban of antibiotic supplementation in animal feed. This ban led to an overall decrease in animal production (Mingmongkolchai & Panbangred, 2018). Probiotics have recently started being used as a less disruptive way to control pathogenic bacteria. In recent years lactic acid bacteria (LAB) are viewed as a biocontrol agents, since can produce bacteriocins like nisin, enterocin. At the same time, organic acids like LA can control pathogenic bacteria due the lowering of the pH itself. LAB can also mitigate the effect of toxic compounds like mycotoxins. By utilising LAB as a probiotic in animal feed it can improve overall weight gain, improve milk quality, reduce infections, enhancing nutrient use, overall digestibility (Vieco-Saiz et al., 2019).

The probiotic characteristics of LAB can also be applied towards the human population. It can be used to treat lactose intolerance, stimulating the immune system, prevention of colon cancer, amongst other benefits (Masood et al., 2011). However, the most commonly used probiotic bacteria LAB and Bifidobacterium are not heat resistant, limiting the use of heat in probiotic food production. This constraint of commercial probiotics can be overcome by utilising spore forming probiotics like B. coagulans (Konuray et al., 2018).

Bacillus coagulans as a probiotic

Bacillus coagulans is a rod gram positive, facultative anaerobic spore forming homofermentative LA producer, belong to the GRAS list (Konuray et al., 2018). The bacteria have two different forms: the vegetative form and the spore form. When spore formers are under abiotic stress like extreme pH, extreme temperature, radiation, nutrient deficiency, etc. they sporulate by condensing its chromosome and develop a thick peptidoglycan rich cortex and a spore coat. If the environmental optimal conditions are met the spore will germinate into a vegetative cell, containing the probiotic characteristics (Cutting, 2011).

These characteristics of B. coagulans make it an interesting probiotic in food processing. By sporulating it can withstand higher temperatures during food manufacturing, but it also can endure months of storage with a high viability and stability (Majeed et al., 2016). Already a few human diet supplements containing B. coagulans are sold under the name of Thorne® (Thorne,

n.d.) and Lactospore® (Sabinsa Corporation, n.d.).

Figure 3: The sporulation scheme of spore forming bacteria under abiotic stress like starvation or high temperatures. When suitable abiotic conditions occur, the bacteria germinate from spores towards a vegetative cell cycle (Cutting, 2011).

Benefits on human health

Different Bacillus species are known to produce bacteriocins which inhibits a broad spectrum of gram-positive pathogens. B. coagulans secretes a bacteriocin called coagulin (Cutting, 2011), which is active against many enteric microbes like E. coli, S. aureus, B. cereus (Konuray et al., 2018). Overall many different probiotic characteristics of B. coagulans are acknowledged: it strengthens the immune system, decreases cholesterol, increases anti-allergy effect. It even mitigates the symptoms of rheumatoid arthritis (Cutting, 2011).

Different independent studies showed the positive effect of B. coagulans on irritable bowel syndrome (IBS), which is a chronic gastrointestinal disorder causing abdominal pain, bloating, diarrhoea, etc. effecting 9% -23% of the world population (Hun, 2009; Rogha et al., 2014). IBS is even linked towards migraine, fibromyalgia and major depressive disorder (MDD) (Cole et al., 2006). In 2018 a placebo controlled clinical study regarding individuals with IBS and MDD was executed. At the end of the 90 day trail the individuals treated with B. coagulans showed a significant improvement (p=0.01) in the quality of life correlating towards IBS and MDD symptoms (Majeed et al., 2018).

Benefits on animal health

B. coagulans can be used as a feed additive for different livestock. Previous studies showed the positive effect of B. coagulans as a probiotic for broiler chickens, piglets and cattle (T. Wu et al., 2018; Y. Wu et al., 2018). A key reason is the antimicrobial activity of Bacillus spp. it

inhibits livestock infections originating from C. perfringens, E. Coli and Staphylococcus (Konuray et al., 2018).

Some Bacillus species can even secrete different extracellular enzyme like cellulase, protease, xylanase, amylase, lipase (Bajpai, 2014) . These enzymes will improve the digestibility of plant material by degrading plant polymers like starch, cellulose and xylan towards more usable sugars and thus increasing the overall lignocellulosic digestibility of plants. Overall Bacillus can affect the animal health and growth by decreasing infections, lowering diarrhea rate, promoting nutrient uptake, increasing digestibility and mitigating oxidative stress (Mingmongkolchai et al., 2018).

By supplementing probiotics in animal feed, the animals will have a greater growth performance, feed conversion rate and survival rate (Fakhri et al., 2019; Patel et al., 2015). By increasing the efficiency of resources utilisation, there will be a significant increase in the global protein production which can be an approach to meet the rising global protein demand. Besides meeting the rising food demand an overall more efficient feed conversion rates also decreases the equivalent CO2 emissions of the livestock agriculture (Cowieson & Selle, 2012).

2.2.2.2 Prebiotics

The composition of the gut microbiota is correlated to different diseases as colon cancer, obesity, depression, IBS, etc. These compositions can be beneficial altered by supplementation of probiotic or prebiotic (Davani-Davari et al., 2019). The FAO/WHO gave a recent definition of prebiotic: “A prebiotic is a nonviable food component that confers a health benefit on the host associated with modulation of the microbiota” (Pineiro et al., 2008).

The microorganisms present in the gut obtain their energy, needed for cell metabolism, from non-digestible carbohydrates in the human diet. These carbohydrates or prebiotics can be fermented by specific bacteria species converting them to compounds associated with a health promoting effect. The most commonly known prebiotics are fructo-oligosaccharides, galacto-oligosaccharides or trans-galacto-galacto-oligosaccharides and will be fermented to short chain fatty acids (SCFA) as LA, butyric acid and propionic acid (Davani-Davari et al., 2019).

The SCFA will maintain the balance of the gut microbiota through inhibition of pathogenic bacteria. These fatty acids will move across the cell membrane and enter in the alkaline cytoplasm. The high pH initiates the dissociating of the SCFA and as a result produces hydrogen protons. As a response, the pathogenic bacteria converge their energy towards the proton pumps and will strive to keep a constant proton gradient and pH. This derives the energy that can be utilised for the actual cell metabolism, inhibiting the cell proliferation (Kalia, 2019).

The supplementation of SCFA is already commercially available in two different sources uncoated or coated feed pellets. However, these products have a few limitations. SCFA are highly water soluble causing them to be adsorbed by the host though not exerting their bacteriocin function. This limitation can be avoided through coating, nevertheless SCFA are producing foul volatile odours and altering the taste of the end product. This makes of poly-b-hydroxybutyrate (PHB), which contains a neutral pallet, an alternative option (Kalia, 2019). PHB is a biopolymer produced by different microorganisms (C. necator, Halomonas, etc.) as a carbon and energy reserve and can be depolymerized into 3-hydroxybutyrate (Quillaguamán et al., 2008). PHB has been studied as a prebiotic in aquaculture where it tends to promote the presence of probiotics as Bacillus sp. and Ruminococcaceau sp. and inhibit pathogenic bacteria as Salmonella sp. and Vibrio sp. Through supplementation of PHB sea bass, Siberian sturgeon and Macrobrachium rosenbergii has an overall increase in survival rate and growth rate (Najdegerami et al., 2012).

2.3 Sustainability of Single Cell Protein production

Besides the nutritional benefits of SCP, there is another main reason the idea is revisited due the sustainability of the process itself compared to the current agricultural practises. The current system is notorious for groundwater contamination, soil erosion, nutrient loss, use of substantial amounts of water and land, greenhouse gas emissions, loss in biodiversity, intensive tillage systems, deforestation of tropical forests all this to maintain the current food demand (Geng et al., 1990; Ridoutt et al., 2014; Tinker et al., 1996).

This year the lungs of the world already lost 7,500 km2 through deforestation, a report showed

that 62 % of all the deforestation areas are for livestock purposes (pastures or soybean cultivation) (Nepstad et al., 2006). The United Nations estimates that by 2050 9.8 billion people will roam this world and with that an increase of 30 - 60 % global crop production (United Nations, 2017). A more sustainable way of food production is required to minimize further impact on the environment (Pikaar et al., 2018; Popp et al., 2017).

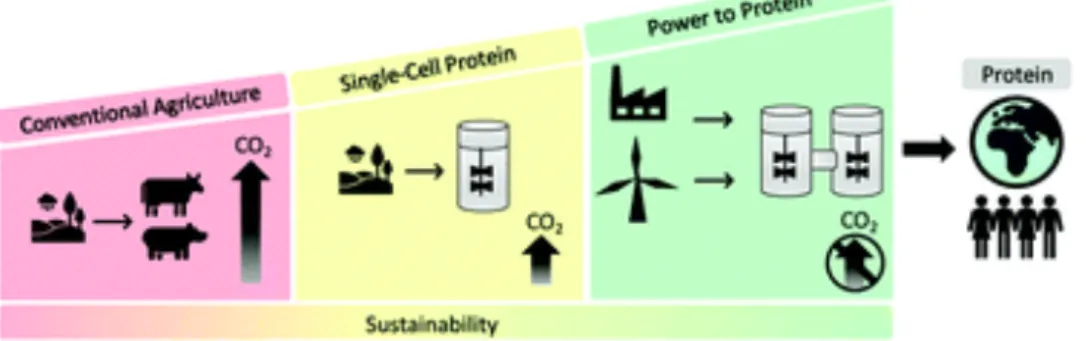

So, why is SCP a more sustainable way to produce proteins (Figure 4)? Microorganisms utilise organics and minerals present in the substrate to convert to protein. This will increase the net protein content of the final product. While animal meat derived from cattle or poultry have a protein conversion efficiency of 3.8% respectively 19.8% (Ritchie et al., 2017), this causes a decrease of the net protein content. A commercial SCP called QuornTM utilise this efficiency to

produce mycoprotein (Finnigan et al., 2019). The production of mycoprotein is also less resource intensive compared to cattle or poultry, QuornTM uses 20 times less water, 90 % less

agricultural land and produce 10 times less CO2 then the production of beef (Quorn, 2019).

However, there more sustainable ways to produce SCP.

Figure 4: The path towards sustainable protein production (Molitor et al., 2019)

Despite all these less resources intensive protein production, there is a potential to produce proteins with different power sources. FeedKind® is a feed supplement for fish, pigs and pets.

It is produced by a gas fermentation based on natural gas. An assessment of the environmental impact of FeedKind® Pellet is made by Calysta®. To make a comparison between conventional

protein sources like soybean and beef the data, shown in Figure 5, is normalised against the protein content of each product. The calculations can be found in appendix 2 (Cumberlege et al., 2016; Geraldes Castanheira & Freire, 2013; Ridoutt et al., 2014, 2011; Willaarts et al., 2011).

Instead of using directly plant material or natural gas, industrial waste streams can be also exploited to produce SCP. Most waste streams are a financial cost to discard, yet this stream can be valorised towards SCP. As an example, can be made in the Belgian potato industry, a collaboration between Agristo, Clarebout and Avecom are developing a SCP called ValProMic (Avecom, n.d.). The water waste stream of fries’ production contains percentage of starch, a carbon source that can be utilised by yeasts like Schwanniomyces alluvius (Avecom, n.d.; Calleja et al., 1986).

Figure 5: Environmental effects of different protein sources. Figure A shows the water footprint of one tonne produced protein. Figure B shows the land footprint of one tonne produced protein. Figure C shows the carbon footprint (in CO2 equivalents) for one tonne of protein.

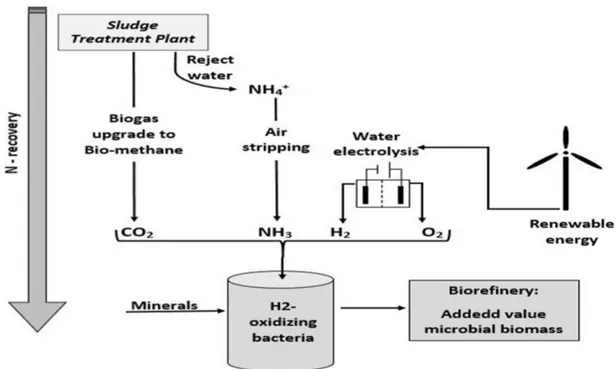

There is even a more circular economic approach to producing SCP through use of N-recovery by utilising ammonia in sewage wastewater (Figure 6). The project is called Power-To-Protein (Figure 6), a pilot scale is being tested in Amsterdam and Enschede. The current artificial nitrogen cycle produces 100 Mt ammonia through the Haber-Bosch process and another 35 Mt ammonia through biological fixation. Only 16 % of the produced ammonia ends up in vegetable or animal proteins due run-off, leaching or inefficient nitrogen to protein conversion (“About – Power to Protein,” n.d.).

The ammonia in the wastewater originates from human urine (Adeva et al., 2012), which can be used by hydrogen-oxidizing bacteria as nitrogen source. The other crucial sources (C-source, oxygen source and electron acceptor) are provided by CO2 emitted by converting biogas to

bio-methane. The electron acceptor (H2) and oxygen is provided by electrolysis powered by

renewable energy. With the rising demand of food and the higher need for reducing environmental impact, SCP can provide a sustainable way of producing protein in the near future (“About – Power to Protein,” n.d.).

326,088 9,663 48 1 10 100 1000 10000 100000 1000000

European Cattle Soybean FeedKind®

Log m 2/t on pr ot ein 529,570 5,375 27 1 10 100 1000 10000 100000 1000000 European Cattle Soybean FeedKind® Log m 3/t on pr ot ein 47,391 17,979 8,196 1 10 100 1000 10000 100000 1000000

European Cattle Soybean FeedKind®

Log k g C O2 e q/t on pr ot ein A B C

Figure 6: The Power-To-Protein power principle (“About – Power to Protein,” n.d.)

3. Restrictions in the use of microorganisms as feed or food

ingredient

So, why are SCP not already integrated in our diet? A few considerations should be made (Table 2) when using SCP as dietary protein source: High investment cost, potential presence of (myco)toxins and high nucleic acids concentration hinder incorporation of SCP in our daily diets. Although algae are a high value nutritious source, they are not directly suitable for human consumption. The problem is the cellulose compound present in the algae cell walls which can be digested by the enzyme cellulase. Humans lack this enzyme, so extra processes are needed to digest the cell walls before it is consumed. Nonetheless, cattle rumen contains bacteria and protozoa with cellulase activity, so algae are a perfect protein supplement for cattle feed (Anupama et al., 2000; Matassa, 2016).

One of the disadvantages of using filamentous fungi or bacteria as SCP, is the production of toxins as secondary metabolites (Anupama et al., 2000). Bacteria can produce different kinds of toxins that cause different diseases like pneumonia, diarrhea, botulism, etc (Schmitt et al., 1999). On the other hand, filamentous fungi can produce mycotoxins, which can cause death, liver cancer, ergotism, etc (Bennett & Klich, 2003). Hence, before consumption as feed or food toxicity tests and analysis are needed to guarantee the safety of the product.

Bacteria and fungi (yeasts and filamentous) contain higher levels of nucleic acids then algae. The degradation of these nucleic acids will form uric acid which cannot be broken down any further by the body. This acid will accumulate and can cause gout or kidney stone formation (Zare et al., 2006). The nucleic acid content of bacteria is around 16% of their dry weight. These

concentrations can be diminished by heat treatment, alkaline hydrolysis, utilisation of RNase, etc. However, with the rising population and resource depletion SCP is reconsidered as a sustainable dietary protein source (Anupama et al., 2000).

Table 2: Overview of advantage and disadvantages of different Single Cell Protein sources (Anupama et al., 2000;

Matassa, 2016)

Microorganism Growth Rate

Substrate Advantage Disadvantages Nutritional value

Algae Lowest Natural light,

CO2 • Vitamins • Microbial oil • Carbohydrates • Protein • Essential amino acids • High contamination risk

• High land footprint

• Hard to harvest • Cell wall digestibility Similar to egg, soy Yeast Quite High

Wide range • Easy to harvest

• Protein

• Essential amino

acids

• Lack of S-amino

acids

Similar to egg and milk

Fungi Low Mostly

lignocellulosic substrates • Easy to harvest • Lignocellulosic substrates • Protein • Essential amino acids

• Low growth rate

• Mycotoxins

Similar to egg and milk

Bacteria Highest Diverse

substrates: animal wastes,

methanol, C1

compounds, etc.

• High growth rate

• Use of inorganic substrates • Protein • Essential amino acids • Endo/exotoxins • Hard to harvest (flocculation) • Lack of S-amino acids Compares to fishmeal

II OBJECTIVES

The green biorefinery generates two fractions, fibre fraction and the grass juice (Figure 7). The fibre fraction can directly be used as a feed ingredient or for biogas production. The main objective of this thesis was to valorise the grass juice towards a high nutritional feed ingredient through SCP production. Grass juice contains vital nutrients for the SCP production but inhibition of spoilage organisms and pathogens is needed for preservation of the juice. A proposed route to preserve the vital nutrients needed for SCP production can be a LA fermentation.

The sub-objectives of this thesis include the preservation of the grass juice through a LA fermentation, performed by a probiotic homofermentative bacterium, namely Bacillus coagulans. A first goal was to maximize the LA production on the grass juice while minimizing production of other organic acids. By maximizing LA production, a more selective SCP production step could be accomplished. To assess the LA production, a (non-)aseptic LA fermentation was evaluated at different temperatures ranging from 28°C till 55°C. Besides grass juice, the fibre fraction, fresh grass and ground grass were evaluated concerning LA production. The second goal was to utilize this LA as a carbon source for Cupriavidus necator, to produce SCP. This was done by evaluating the specific growth rates at different initial LA concentrations

A third sub-objective was an assessment on two different proposed SCP production approaches. Two different SCP production methods were evaluated. A first approach sequential consisted out of two steps, a LA fermentation followed by directly by an aerobic SCP production step. The second approach was electrochemically extraction of lactate from the LA fermented grass juice. This concentrated extract was then used in a carbon absent synthetic medium for the cultivation of C. necator.

At last the potential of the green biorefinery SCP production was assessed based on excess grass biomass currently present in Europe.